Maintaining a big advantage...

One thing has become apparent over the last few years: if Europe wants to be able to defy the competition of emerging countries, new innovations have to be brought out constantly, the latest technology must always be used and productivity must be continually increased. This is especially true of the aircraft industry, where our Asian competitors are very keen on catching up quickly. The French aircraft manufacturer DASSAULT has taken this on board and is mastering the use of special forming technology for the wings of its planes, especially the FALCON aircraft, which continues to be a notable success.

Until recently, this forming work step was carried out with conventional – even manual – methods and a lot of know-how. Increasing the productivity, whilst at the same time guaranteeing precision, repeatability and traceability, could not be done without automating the process. SERMATI (society for planning and realising assembly lines and special machines) was therefore commissioned to automate the pressing plant. SERMATI turned to NUM to integrate the Flexium system (CNC, drives, motors), design the process control and produce the specific HMIs.

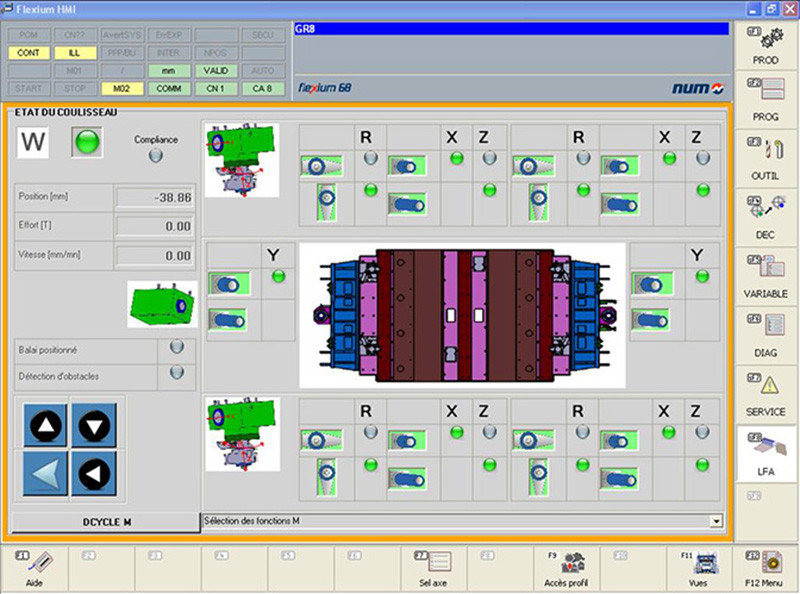

The technical process is of course confidential, but an outline of the customer requirements that needed to be fulfilled is given here. First, imagine a machine that is large enough to fit an entire wing inside. This machine comprises six units driven by 18 motors, each of which develops a torque of more than 120 Nm. Each unit consists of two or four axes that can be moved completely independently, partially or entirely in sync. Each unit carries out a very special function. The synchronisation between the units must be extremely precise and as simple as possible to achieve. The machine also communicates with a conveyor system, which positions the necessary tool and the workpiece to be machined when needed, transporting the latter to the next machining station after the work step has been completed. The conveyor system communicates closely with other systems, in order to ensure that the workpieces can be transported quickly and without a hitch.

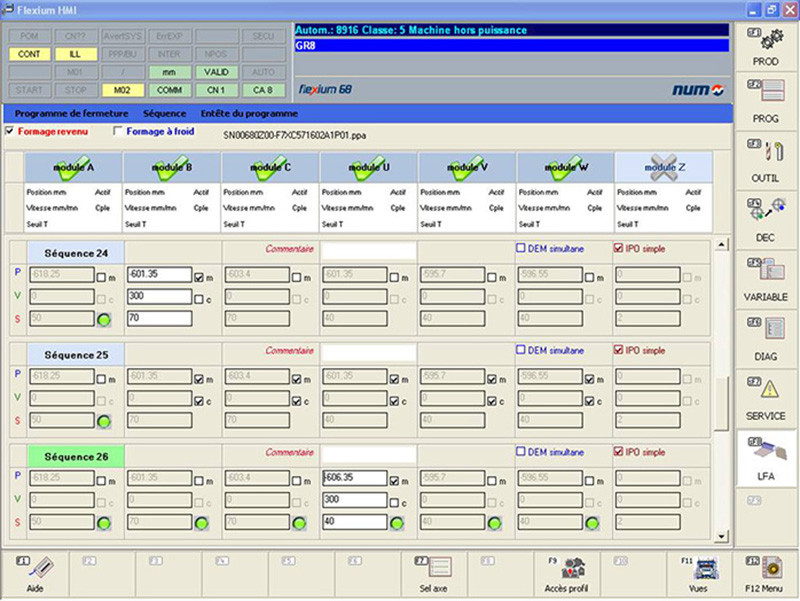

The machining itself is generally programmed using a teach-in box. Numerous parameters, such as movement, pressure, temperature, time, etc., need to be checked constantly, in order to avoid anything happening that could pose a risk to the operator, equipment or the workpiece. The system monitors and records all relevant data, regardless of whether the programme being executed is standard or based on teach-in. It goes without saying that full operational safety must be ensured and both programming and operation must be simple and user-friendly.

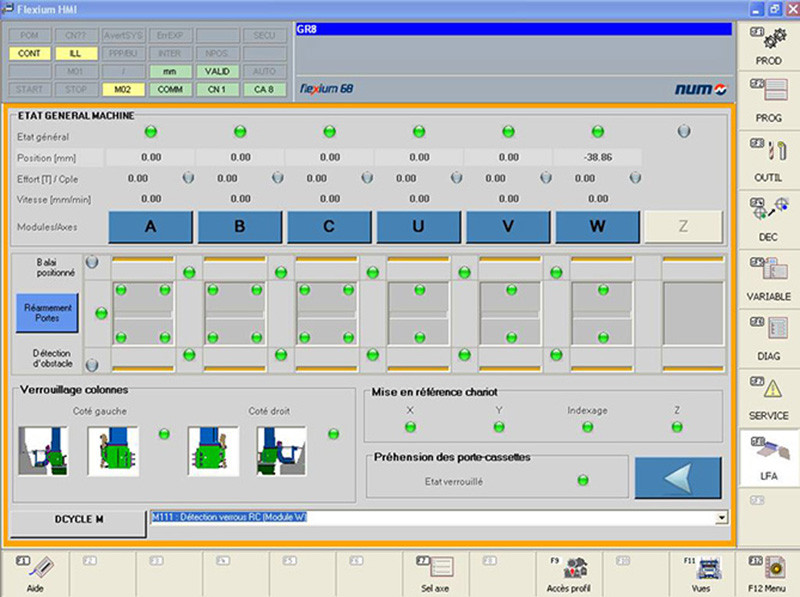

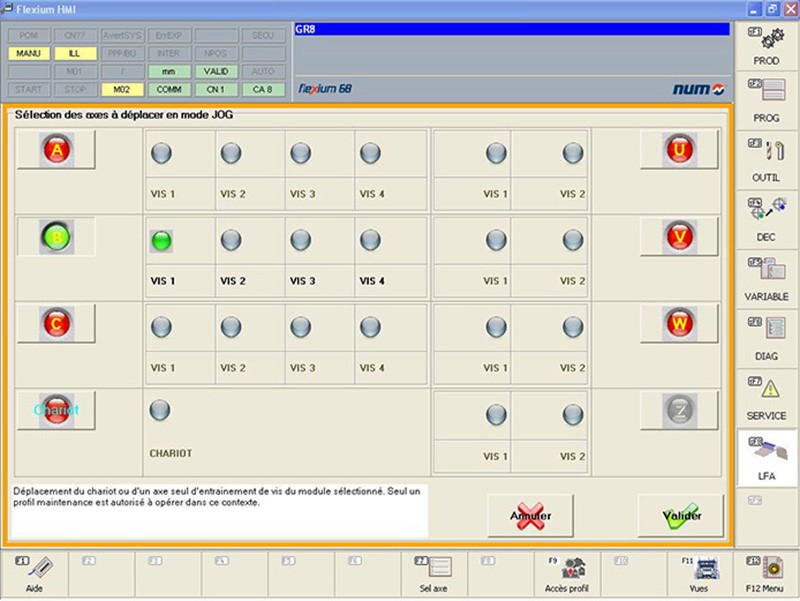

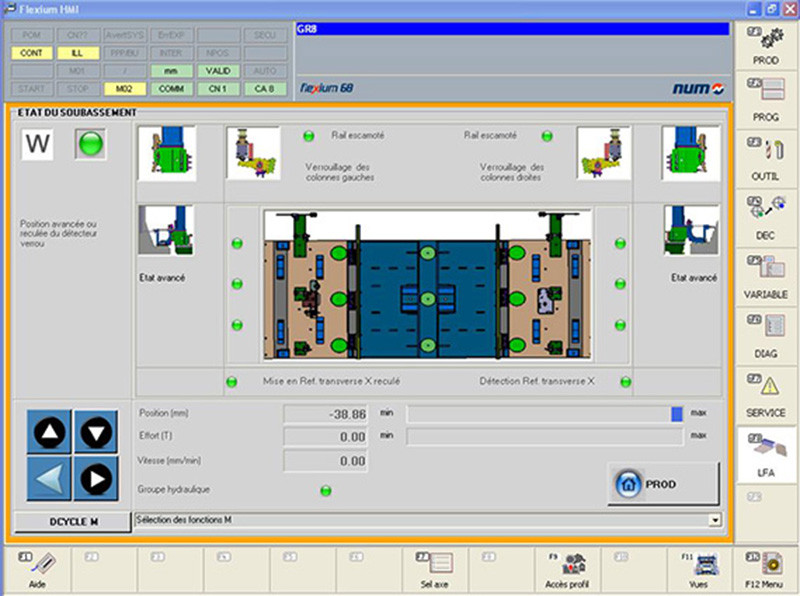

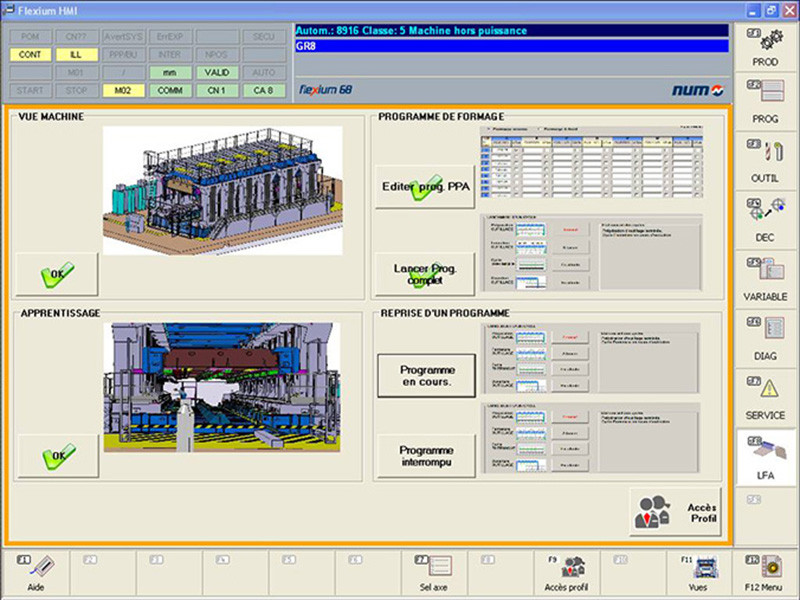

To this end, a human-machine interface was developed to fit the requirements of the operators and the maintenance staff. These requirements, which the engineers at NUM faced, were diverse. They included a high number of axes to control, a great many inputs and outputs, and the need for a reliable, safe and user-friendly solution.

The servo drives, which are connected to the control via DIC-NT, are of particular importance in this system. After the axes have been initialised, they are assigned to the different CNC channels based on the NC program and synchronised on the fly, depending on the requirements. Each axis can be a master, slave or completely independent. The integrated safety function, SAM, ensures that the movement is safe in all situations. The digital bus also allows a wide range of information to be fed back, which is used for both process control and tracking.

It was feared that programming six units, sometimes working independently, would quickly cause a real headache. To avoid this, all axis movement is controlled from a single workpiece programme. This uses functions such as symbolic programming, automatically generated tables and dynamic operators.

A large number of SPS units are connected to the Flexium system via fieldbus. The range extends from simple sensors to intelligent instruments, spread out over the whole machine. As well as the actual machine control, the SPS units also constantly monitor the functions of the attached modules. In case a fault occurs (such as a wire breaking), individual emergency withdrawal positions have been defined, further increasing the safety of the system. A special graphical HMI was developed to fulfil the requirement of simple operation. The HMI is based on the FXServer and is written in a high-level language. The contextual HMI ensures the machine can be controlled and the diagnosis and programming can be carried out via the teach-in box. The machine is currently in the commissioning phase at DASSAULT Aviation in Seclin and according to Jean-François ROUX, head of industrial resources:

“The high level of engagement by NUM, together with their willingness to listen and fulfil the customer’s needs, has made the development of this innovative process in accordance with the main specifications possible. The choice of NUM and the Flexium CNC system for this special process has proved beyond doubt to have been the right one. The great strength of the Flexium CNC system is demonstrated by the precise control of 18 synchronous channels, and the user-friendly graphical human-machine interface.”

(September 2011)