Seventy tons overhead

We do not always consider the wear and tear that wheels and axles of rolling stock, used on trains or trams, are exposed to. Sliding on the leaves in autumn, emergency braking, shocks - all these remain in memory in the metal of the axles. And yet this is the first safety component, which is why these elements are subject to very careful attention and maintenance.

To ensure this maintenance, the SNCF technicentre in Noisy le Sec, northeast of Paris, has just equipped itself with a new Koltech underfloor wheelset lathe, the special feature of which is that it can process tram-trains. Indeed, with the extension of cities, tramways are required to use not only the urban network but also the nearby rail network and there are now vehicles capable of running on both types of track. They are commonly referred to as tram-trains and the new T4 tramway to the north-east of Paris is one of them.

An underfloor wheelset lathe is always an impressive machine. Imagine being in a deep niche and the seventy tons of a tramway, or the four hundred tons of a TGV (High Speed Train), slowly pass over you, and stop just a little forward to position an axle above four rollers; then a little more than one meter of rails disappear, this part of the train being held only by the rollers that will drive the axle in rotation to bring it back into condition.

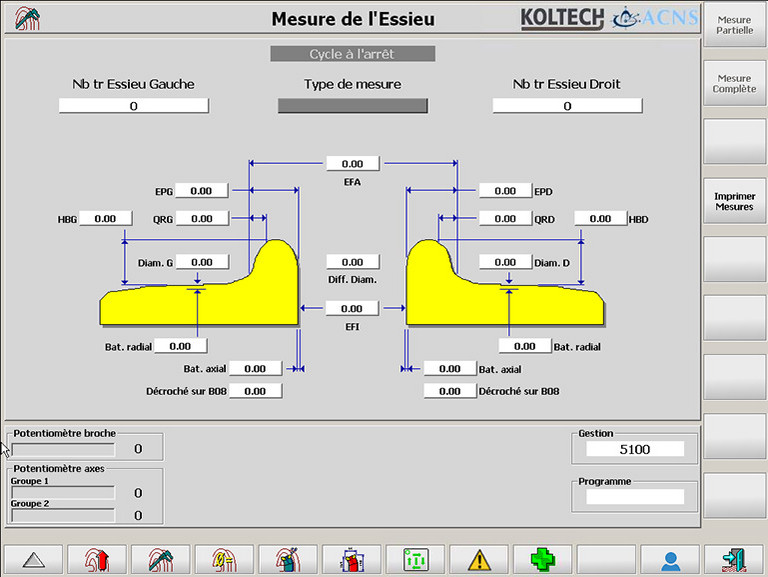

A machining sequence begins with the identification of the axle and wheel profile, after which the cycle will measure the diameter of each wheel and their spacing. The operator can then access certain parameters to optimize them and will define the machining sequence to bring the profile back within the desired tolerance. The production of the profile requires a high degree of precision. The rolling stock wheels have a slightly conical profile and a flange on one side to keep them on the track. There is also a small amount of axial play. When the rolling stock is travelling around a bend in the track, the slope of the profile means that the two wheels on an axle present slightly different diameters to the track surface, and are therefore able to accommodate the required speed difference. This feature also allows a slight tolerance on the difference in diameters and therefore the optimization of material removal. A machining operation consists of several phases, the operator can choose the execution order, but the application ensures that all phases have been successfully executed before the operation can be considered complete.

SNCF has long trusted NUM for its equipment. During the retrofits it carried out, the SNCF expertise center defined an operating mode and ergonomics perfectly adapted to this type of machining. This operating mode, originally developed on NUM’s 1060 CNC system, is found on several dozen machines distributed in the maintenance workshops. It has, of course, evolved to take into account the increased performance of control systems, but the philosophy remains unchanged.

The machine we are interested in today is the result of cooperation between SNCF, the Polish manufacturer KOLTECH and the engineering and manufacturing company ACNS, which has been supporting KOLTECH on the French market since 2014. To this end, ACNS, which has been a long-standing NUM partner, has chosen a Flexium+ 68 together with SNCF. Mr. Hendriksen, its Director, explains why: “One of the advantages of NUM products is their adaptability and ease of integration, our engineers can quickly master the different aspects and NUM support is always available; moreover, the compatibility of the part programs with previous systems is a major asset for our customers.“

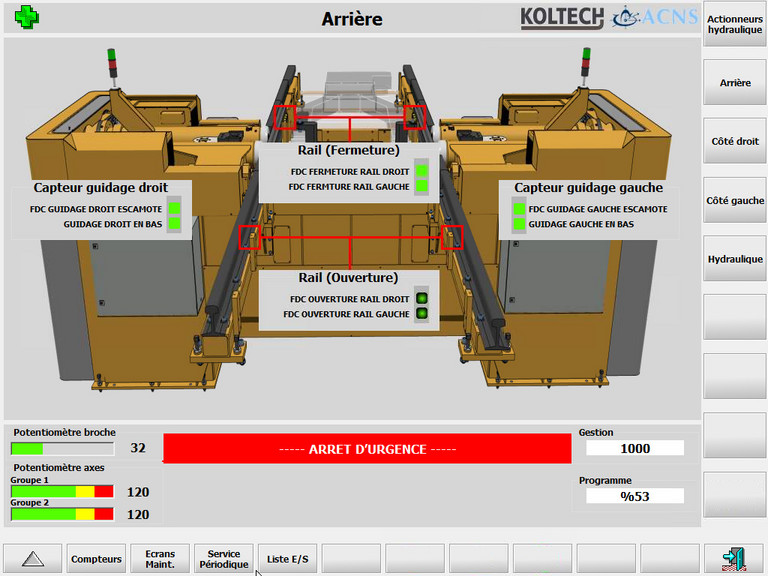

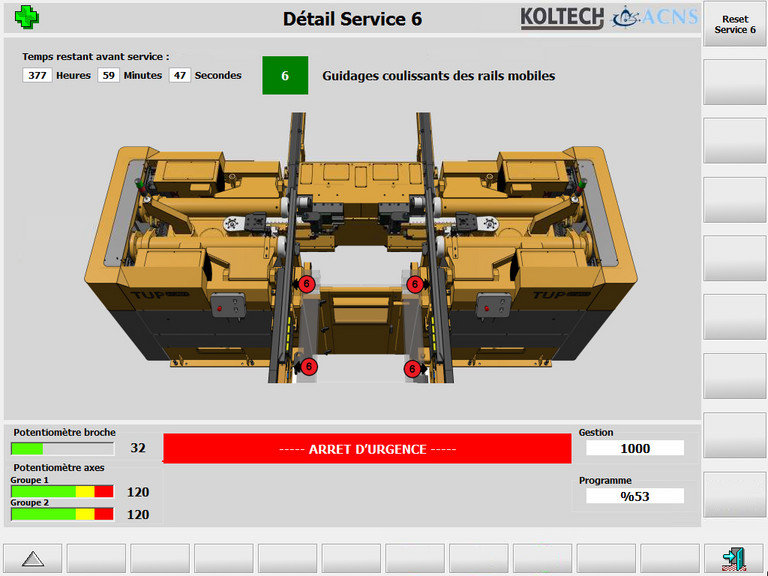

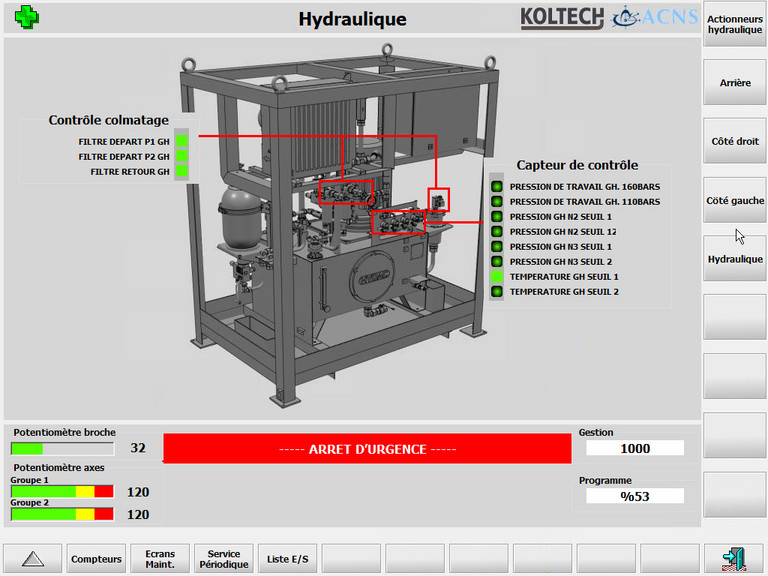

The equipment includes four BPH155 motors for right and left machining carriages, four AMS132 10kW spindle motors driven by MDLUX 130A drives with STOX (Safe Torque Off) function, all connected to a regenerative power supply and completed by four measurement inputs on EtherCAT for determining the diameter and center distance of the wheels. The NUMSafe safety PLC monitors the whole system. The man-machine interface is provided by an MP04 machine console and a 15” FS152 screen console which presents the pages of the operating mode defined by the SNCF. This ergonomic user interface has been developed in C and communicates with the CNC and PLC via FXServer, the standard NUM interface is not displayed in this case.

One of the difficulties that can be encountered with these kinds of lathes concerns the rotation of the axle that will be machined. As it remains in place on the train it cannot be clamped and is only frictionally driven by four rollers. It is therefore necessary to perfectly synchronize the speeds of the two rollers of the same wheel and to take into account the difference in diameter for the synchronization between the right and left wheels. Thanks to the precision of the MDLUX digital drives, it was not necessary to perform torque synchronization which could generate slippages. The drives of the right side receive the same speed setpoint and those on the left side receive a value proportional to the diameter ratio. This solution is perfectly satisfactory.

Mr. Kleiber, the SNCF expert in wheelset lathes who carried out the first retrofits and defined the ergonomics and operating procedures of these machines, tells us: “I also appreciate the ease of integration of NUM products and then we always have a contact person for after-sales service or development. We are very satisfied with this cooperation and the performance of the products, the integration of new functionalities is planned.“

Simplicity, performance, proximity, these qualifiers are often mentioned as part of NUM’s assets. Thanks to them, partnerships are established that will allow you to highlight your competitive advantages. Do not hesitate to discuss with your correspondents so that you too can benefit.

(September 2019)