Production of spiral bevel gears with a CNC hypoid automatic hobbing machine and NUMgear

Didimo Zanetti, an Italian company located in Casalecchio di Reno, Bolzano province, produces drive elements for backhoe loaders, tractors and haulage vehicles. The company, which was founded in 1952 by Didimo Zanetti, is currently managed by his son, Andrea Zanetti, who serves as managing director. Production is split into two parts: Ninety-five percent consists of parts for differential and speed-change gearboxes for the original equipment and the rest consists of parts, which are intended as replacement parts.

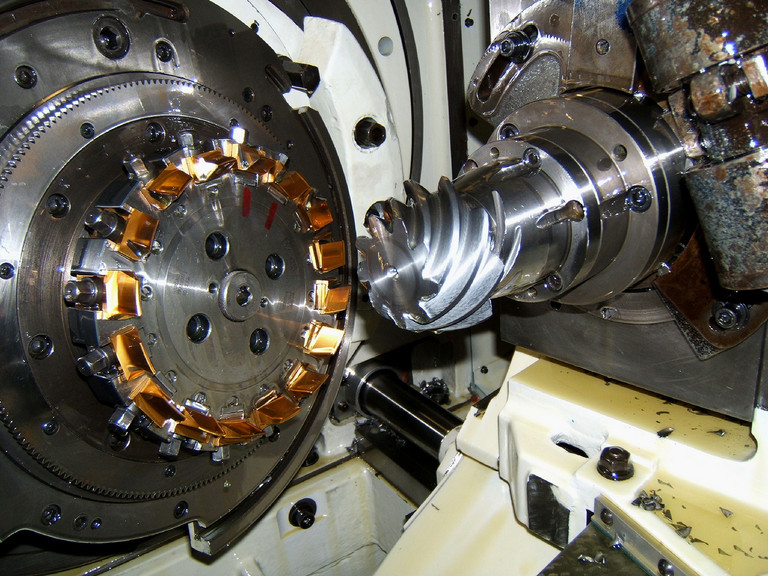

The company has decided to convert the Gleason model 641 mechanical hypoid automatic hobbing machine, which is used for manufacturing spiral bevel gears, sprocket wheels and rims, into an CNC machine.

The primary goal has been to avoid costly tests and inspections of the machine in order to repair mechanical malfunctions due to wear from intensive use of the machine during extensive production uptimes. Such tests must be carried out by qualified personnel, which are increasingly difficult to find. Even an occasional mechanical problem causes considerable difficulties in completing a production lot and complicates the company’s production planning.

Lanzi snc di Ozzano Dell’Emilia from the province of Bologna was selected to carry out the machine transformation project. The company founded in 1964 by Francesco Lanzi is currently headed by his son Luigi Lanzi and is engaged in modernising machine tools. Ninety percent of the companies operation is geared for the Italian market. For this project, NUM has contributed its NUMGear all-in-one solution, based on the Axium Power CNC System. To implement the work cycles, the company cooperated closely with Didimo Zanetti’s quality representatives for spiral bevel gears, in order to incorporate their knowledge and experience of many years in spiral bevel gear production.

Another important contribution from NUM to this project has been its support in identifying optimal parameters for control of these special gears. In this respect, the cooperation paid particularly off with Luigi Lanzi, who perfectly re-engineered the machine’s electromechanics and was even able to achieve an optimal dynamic balance between the electronics and mechanical components.

The quality of the NUM servo drives, the interpolation of the traverse path via the NUM Axium Power CNC, and the simple programming, for example, with macro commands, have also led to the machine’s higher flexibility during the adjustment phase. Due to the introduction of the Helical Motion Technique, the cutting phase for the bevel wheel has been improved. The simultaneous interpolation of the holding device’s axes for the workpiece and of the sliding carriage was not possible with the previous machine. Production was started in early December 2007 and approximately 30,000 bevel wheels were produced within one month despite the holiday season.

No problems arose which would have required production to stop. The retrofit has led to a reduction in production time of about 15% and an improvement in the quality of the parts manufactured. The success resulting from consistently pursuing the original project goals and the subsequent improvement of the production parameters, has led the management of Didimo Zanetti to commission a new project to retrofit the production units from the plant located in Casalecchio di Reno.

(April 2008)