NUM releases major update to NUMROTO tool grinding software

Features new generation of profile editor, completely revised user administration and a host of new functions

NUM has released a major update to its renowned NUMROTO tool grinding software which includes a host of new functions to further accelerate the productivity of tool grinding machines.

Version 5.0.0 of NUMROTO provides CNC grinding machine users with an unprecedented level of flexibility. It is likely to be of especial interest to tool manufacturers seeking to increase their productivity of precision drills, subland step drills, end mills and form tools.

NUMROTO features a true multiuser environment. The new version of the software allows much more detailed definition of user administration rights, to help improve machine management and better protect valuable machining data.

NUM has significantly enhanced the speed, functionality and ergonomics of NUMROTO’s profile editor. The new Profile Editor X enables contour lines and radii to be drawn using a computer mouse, with all elements clearly displayed in tabular form and with one-click sizing information. When importing a DXF file, all existing layers are displayed in a preview window. Profile Editor X also offers a spline to polyline conversion facility, enabling splines to be read in and automatically converted to segmented lines with a maximum user-specified tolerance.

NUMROTO 5.0.0 introduces two new functions for machining drills and step drills, and no less than seven new functions for end mill production. When using a peripheral grinding wheel for chamfer relief of a drill, the inside or outside edge of the wheel can be selected. And at the end of a clearance relief operation on a drill, it is now possible to program a disengage chamfer.

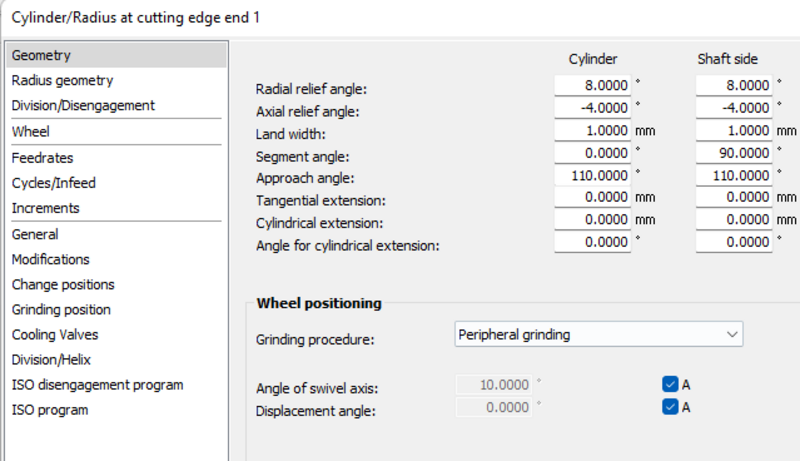

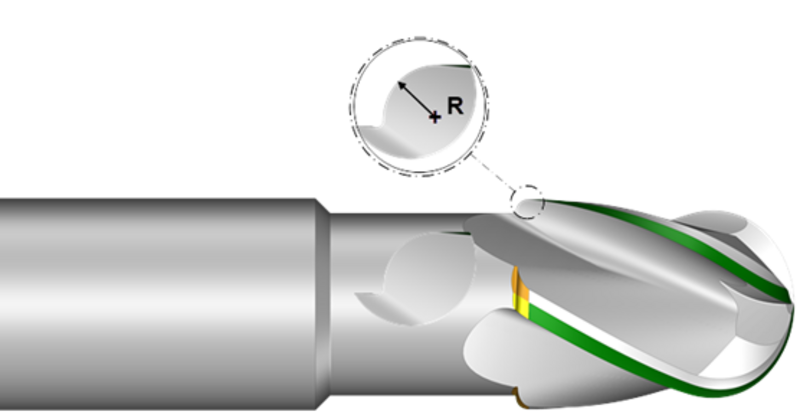

The new functions for end mills encompass a multitude of machining operations and read like a user’s ‘wish list’. Up and down cutting is now possible and employs a simplified geometry dialogue. New functions are available to simplify the cutting of S-shaped and straight chisel edges, and with separate increments for ball relief chisel edges. A radius can now be ground at the end of the cutting length. Separate feed rates can be programmed for the grinding wheel engagement and disengagement slants – and the cutting and displacement angle of relief operations can now be individually programmed for groups of teeth.

First launched in 1987, NUMROTO software has become the preferred choice for many of the world’s leading manufacturers of CNC machines for the production and re-sharpening of tools such as end-mills, drills, step drills, form cutters and many others. Compared to most competitive products on the market, the software provides a much more direct and efficient path between tool design, manufacture and verification.

NUMROTO software is currently used on more than 100 different types of machines from 20 prestigious international manufacturers in 50 countries worldwide.