Advanced joinery machining centre uses state-of-the-art CNC technology

Graf-Holztechnik GmbH combines craftsmanship and design know-how in wood processing with state-of-the-art CNC technologies from NUM, which considerably increases production efficiency. This improvement was made possible thanks to the HAGEwood CNC joinery machining centre fitted with a Flexium CNC from NUM.

Wood is a fascinating, sustainable and therefore environmentally friendly material with an attractive look and a range of benefits. Graf-Holztechnik, whose state-of-the-art production site is situated in the forest district of Horn, develops cost-effective and creative solutions from wood, from conventional carpentry via renovation projects to ambitious designs and elemental constructions with short building times (e.g. the Stetten Fossil World viewing platform). From static and design planning through production to on-site assembly, everything is carried out autonomously by skilled employees using the latest computer technology.

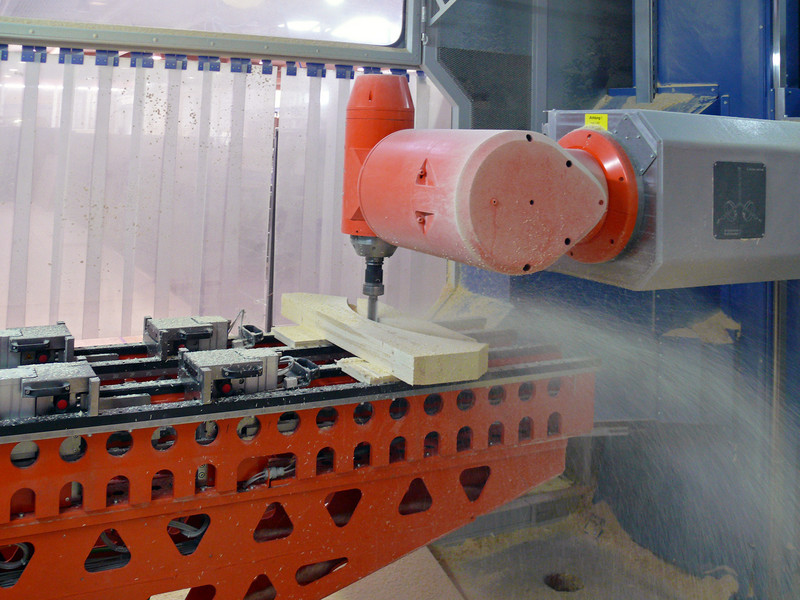

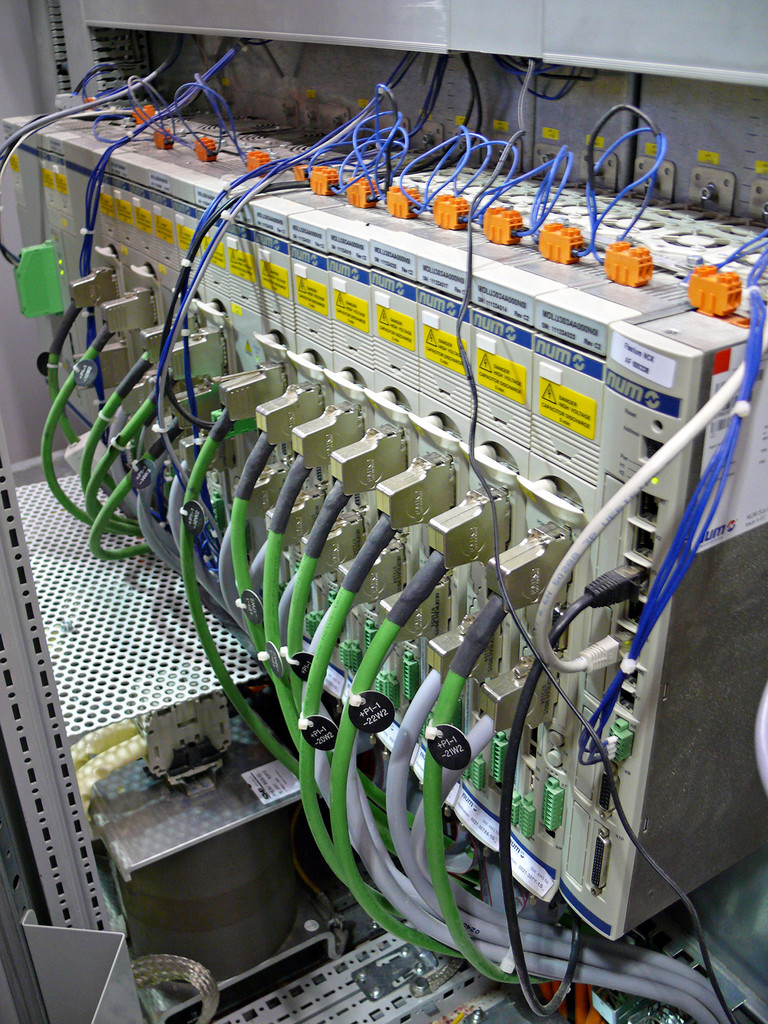

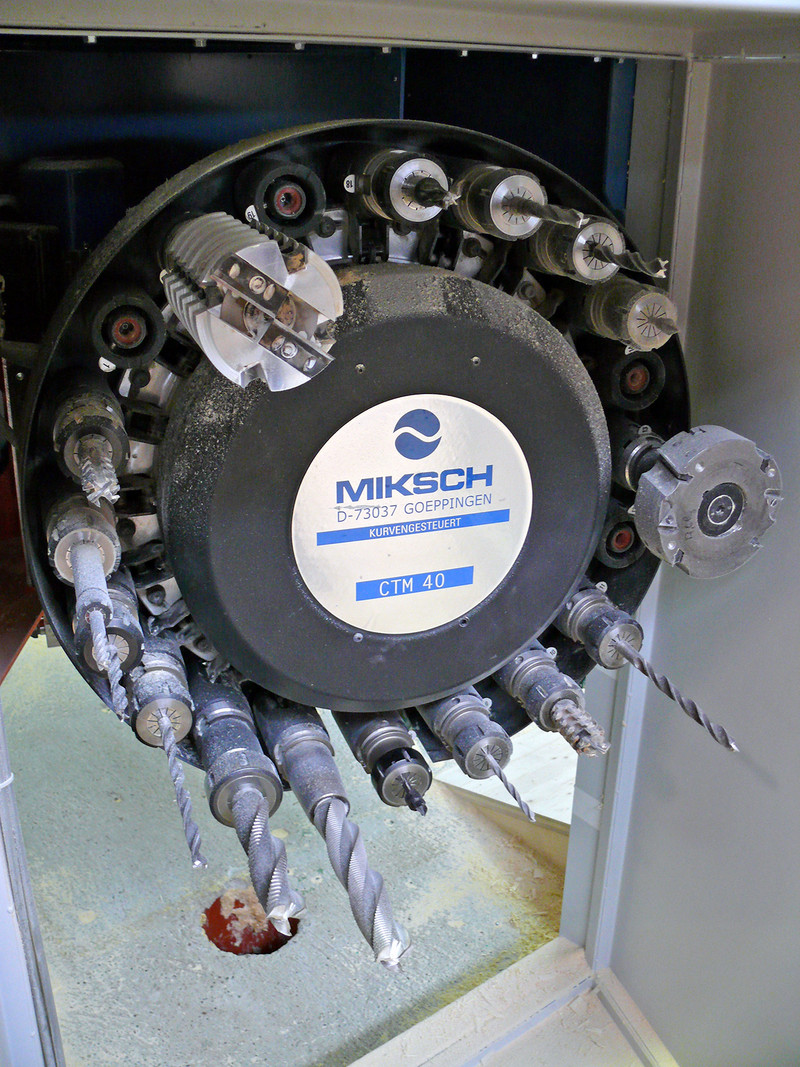

The components are designed in three dimensions on a CAD system, from which the machine data is derived and processed fully automatically on the CNC-controlled machine. Graf-Holztechnik has two CNC joinery centres and a CNC production system for compound systems. The latest system is the HAGEwood CNC joinery machining centre, which successfully went into service last year. This system is fitted with a Flexium 68 CNC from NUM and has 10 axes, 5-axis interpolation and RTCP. The X axes can be operated both in a master-slave configuration and individually. A special collision monitoring system is activated during single-mode operation to prevent collisions of the X axes. The heart of the system is the twin-axis milling head, which can spin continuously and machine the workpiece from all sides. The fluid-cooled 22 kW IBAG spindle accelerates the tool up to 12,000 rpm. The milling head collects the 24 different tools from the magazine itself. A 20-way tool drum changer from Miksch for drilling and milling tools, and a linear 4-way overhead special tool changer for saw blades up to 800 millimetres in diameter guarantee the flexibility of the system.

The HAGEwood can process components up to 25 metres long, 2.70 metres wide and 90 centimetres high with an overall weight of 9 tonnes. Depending on their size, the components are tensioned on a maximum of 6 supports, which are fitted with a pneumatic fast-tensioning system. This fast-tensioning system is width- and height-adjustable. The 6 supports are arranged asymmetrically so they can be brought together completely. The fast-tensioning system is controlled via the control panel for the CNC. Individual long components or up to 4 smaller components can be tensioned on the 6 supports at the same time. The coordinates of each component are calculated individually for the CNC by means of 4 laser measurement systems.

Precision wood processing is extremely important for the type of major joinery projects that Graf-Holztechnik GmbH regularly handles. The machine’s high level of rigidity across its whole trajectory and its weight of 30 tonnes translate into precision levels of 0.1 millimetres. This is not something you find often in the timber industry. The HAGEwood provides various benefits for Graf-Holztechnik GmbH, the most important of which is the time saving. Because the workpieces can now be machined from all 6 sides, there is no need to reposition them during production. This is a huge advantage as it eliminates many previous error sources. The extremely high productivity is supported by the strong spindle and the high maximum advance speeds of 80 metres/minute for the X axes and 40 metres/minute for the Y and Z axes. The modular construction makes the set-up of the system very flexible. This modularity is fully supported by the flexible CNC. As well as flexibility, easy maintenance of the system is also key. For example, the machining spindle is easy to access from all sides. And, last but not least, close attention has been paid to the operation of the system. In order to improve user-friendliness, the system can be controlled directly via a touch panel on the machine or from a PC.

Perfect cooperation between customer Graf-Holztechnik GmbH, the machine manufacturer HAGE and CNC system manufacturer NUM has resulted in a high-precision, extremely economical CNC joinery machine.

(September 2013)