EBC - Earlier Block Change

NUM has introduced various new CNC functions and programming improvements with the latest 4.1.20.00 version of Flexium+.

One of these new functions is called EBC (Earlier Block Change). EBC facilitates faster machining cycles, because the NCK (NC kernel) starts execution of the next block before the previous block has terminated.

EBC also provides a very fast signal exchange between the PLC and the part program, allowing the PLC to control and get information about program execution using 32 dedicated input bits and 32 dedicated output bits.

Block change can now occur under a variety of conditions:

- Immediately – the two blocks are therefore executed simultaneously.

- After a certain distance has been traversed.

- When the residual distance is lower than a value.

- When the PLC sets a certain signal.

- When the block ends normally (standard way).

Furthermore, the NCK communicates to the PLC when certain conditions in the program execution have been reached, allowing the PLC to start auxiliary operations without the need to program M functions – and thus without stopping any axes.

All of these features are easily programmed with a single G function and a few parameters.

For example:

G777+ Q1 D80

G1 X100

G1 Y100 Z100

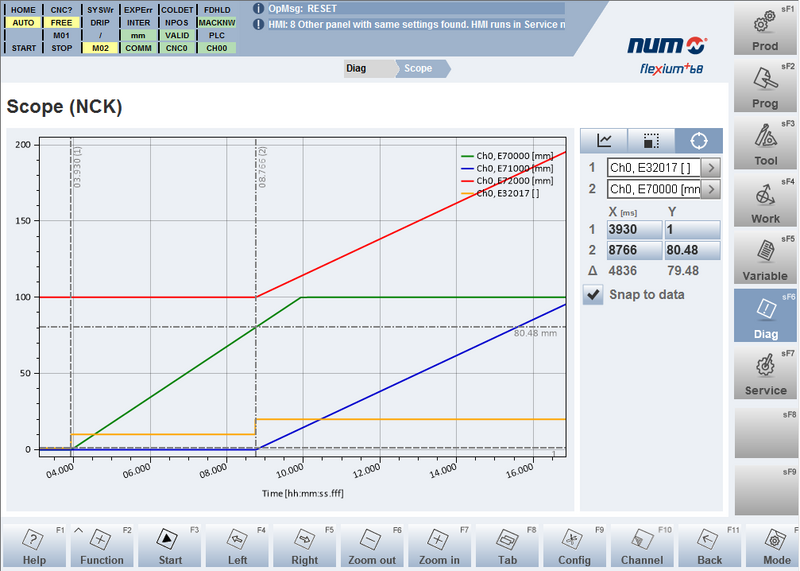

Short Test: (Y/Z axes will start when X axis reaches 80 mm position) Visualization of axes movements in HMI Scope function time / position diagram

Legend:

- Green: Position reference of X

- Blue: Position reference of Y

- Red: Position reference of Z

- Yellow: Current block number in execution