Position encoders then and now

For digitally operating electronic measuring devices and controls, encoders are required which report a rotation angle or position in digital form. NUM developed an absolute encoder as early as 1960, at that time still under the company name Güttinger.

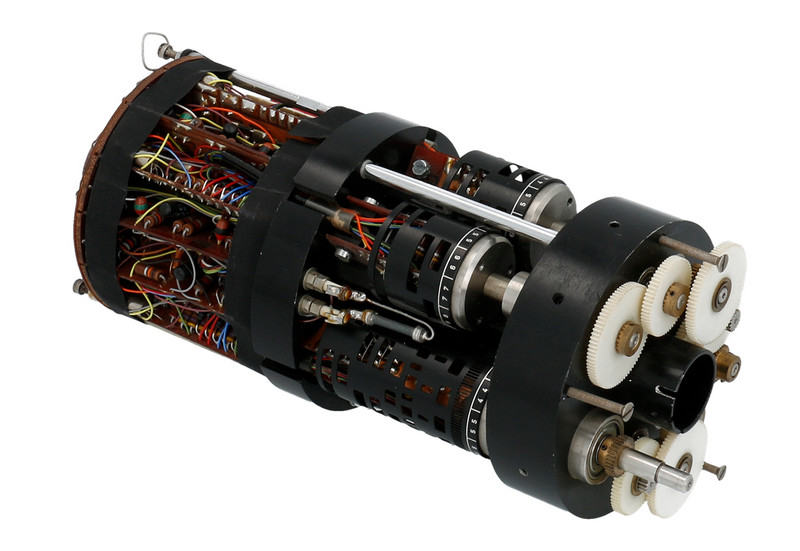

Absolute encoder in 1960

The absolute encoder measures the angle of rotation of a shaft and outputs the measured value as a six-digit decimal number. The encoder had five drums on which the digits were milled in a special Güttinger code. In this code, only one bit changed from number to number. The first drum had the numbers from 00 to 99. The encoder had, therefore, a resolution of 100 positions per revolution and the capability to code up to 10.000 revolutions. The drum with the highest resolution also contained a speedometer track.

Later, the Gray code was chosen for absolute encoders, also a one-step code in which only 1-bit changes per step. It was invented and patented for data transmission in 1953. In the 1960s, the pioneering days of electronics, its practical use in devices was unimaginable due to the high effort required for decoding.

How was this problem solved at NUM (then Güttinger) without Gray code?

The measuring range was divided into 6 drum sections of one decade each. For each decade a NUM-own 4-bit one-step code was milled into the drums. The code was selected so that the milling did not endanger the stability of the drums and was converted directly in the encoder into a BCD (binary coded decimal code) near code.

Fields of application

In 1966, the NUM encoder enabled, for example, the Knorr company in Thayngen, Germany, to avoid having to move to reference point after a power failure because the position was not lost and therefore work could continue without problems and long downtimes.

The encoders were also used in nuclear power plants for the fuel rod robots as well as for the Grand Dixance reservoir power plant. The encoder was also used on Coradomats (drawing tables) in the X and Y-axis. CERN in Meyrin also used such an encoder.

Absolute encoder today

Since 1960 the encoders have undergone further technical and external development. The volume has been reduced by a factor 40 and resolution increased by 168.000 times.

As well as very small, robust and reliable, the newest NUM’s encoders have got an extremely high resolution per revolution (24 bits equivalent to more than 16 million positions per revolution) an overall accuracy of ± 25 arcsec and the capability of coding up to 4096 revolutions.

Who experienced to wire high-end encoder knows that it is not easy at all; twisted pairs, shielding connections, complex-soldering operations, etc. All this is history. The new NUM encoders, integrated in SHX and SPX servomotors, are connected just by using two wires. On these two wires power supply and digital data are transmitted at a very highly rated. The NUMDrive X servo drive, to which the encoders are connected, can cyclically read the encoder position with a sampling time of 25 µs.

All these features make the high-resolution NUM’s encoders unique on the market.