Custom CNC is at heart of groundbreaking laser cutting machine

special CNC technology – and a unique flying optical system – help the new machine to slash traditional pricing levels

Customized CNC technology from NUM is helping the laser cutting machine manufacturer Favor Laser to accelerate product development and address new markets. Using special hardware and software designed by NUM, the Taiwanese company has developed a high precision laser cutter that is capable of producing very small or very large parts from sheet metal, with a feed rate of up to 60 meters per minute. This new machine will mark Favor Laser’s entry into the high performance end of the market, which the company intends to penetrate rapidly through a groundbreaking combination of performance and highly aggressive pricing that will reduce the costs of these machines by some 20 percent.

Founded in 1994, Favor Laser is based in New Taipei City, Taiwan, with additional sales and manufacturing facilities in Shanghai, China. Until now, the company has concentrated on producing laser cutters for the low cost end of the market, offering four ranges of machine to suit different sheet metal fabrication requirements such as small batch size manufacturing, precision cutting of small parts, or high volume production of larger parts.

In 2010, Favor Laser took the strategic decision to extend its product range by developing a high performance multi-capability laser cutting machine for the international market, which is currently dominated by a small number of Swiss, German and Japanese manufacturers. The company’s initial research indicated that by combining its laser cutting technology with value-engineered hardware and advanced CNC software, it would be able to produce a machine with the same performance as the market leaders, but at significantly lower cost.

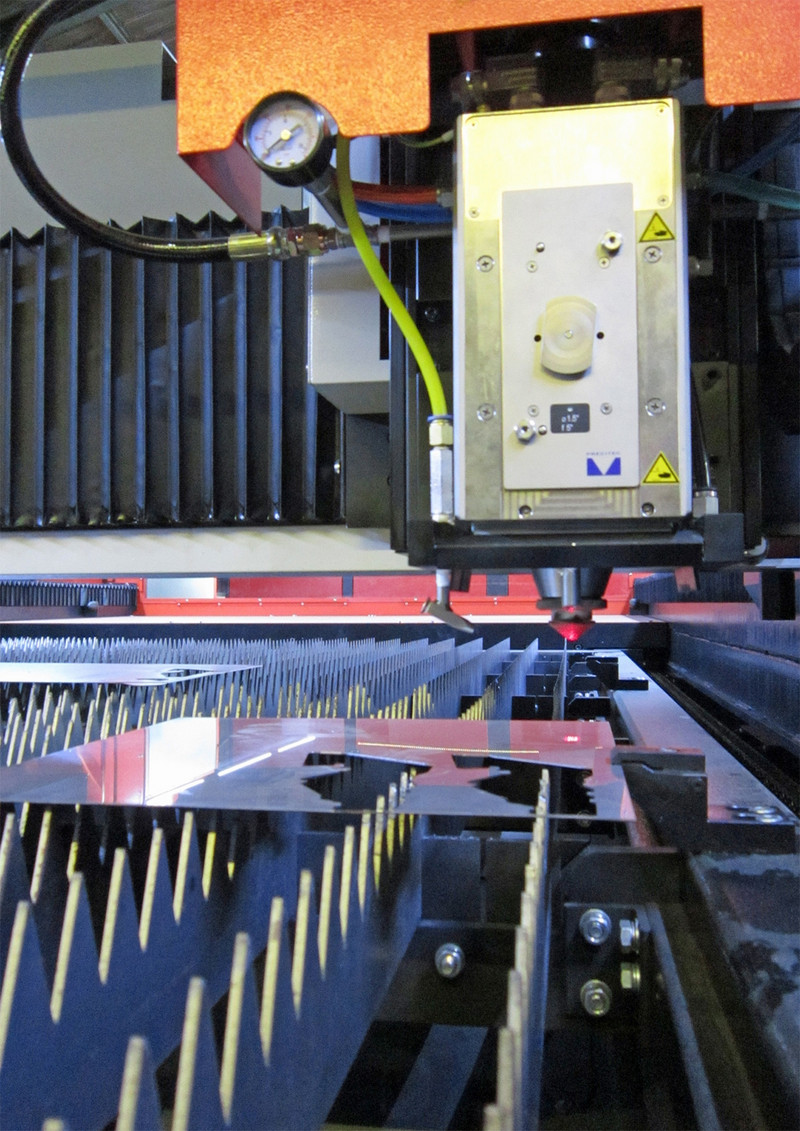

All Favor Laser machines are based on an innovative flying optics system, where the metal sheet that is being cut is supported on a stationary table, and the cutting head which directs the laser beam is moved horizontally above the surface of the sheet. This approach has several significant advantages over machines that move the workpiece beneath a static laser beam. The cutting head has a low and constant mass which facilitates fast and precise positioning, whereas moving the workpiece – which changes mass throughout the cutting process – is slower and more difficult to achieve, demanding complex and expensive motion control systems to maintain cutting accuracy. As well as improving machine throughput and productivity, when cutting thin material the faster cutting speed of flying optic laser cutters helps prevent heat build-up deforming the workpiece.

Favor Laser’s new XO high performance laser cutter is a four axis machine, but uses two motors for the X axis. Horizontal positioning of the cutting head is handled by the X and Y axes, while the Z axis controls the height of the head above the surface of the workpiece and the fourth (U) axis is used for loading and unloading material. Patented adaptive optics compensate for the length of laser beam, which varies depending on the position of the cutting head relative to the laser oscillator. A high speed servo is used for the Z axis – the gap between the cutting head and workpiece is continually monitored and adjusted to maintain beam focus and maximize cutting efficiency.

After investigating various CNC options, Favor Laser was keen to use NUM’s Flexium 68 CNC system for its new XO machine. The CNC was chosen for both hardware and software reasons: Flexium 68's motion control hardware very closely matched the control required for this type of machine – plus it included built-in configuration flexibility for future enhancements – and it offered unique software functionality that would simplify application programming. In particular, the ‘Dynamic Operator’ (DO) function, which is unique to NUM, was judged ideal for the program that dynamically controls the gap between the cutting head and the workpiece. By using fast calculation and communication facilities, the DO function enables event-driven machine cycles to be integrated into the real-time CNC kernel.

Favor Laser also sought a CNC systems supplier that was prepared to actively participate in development of the XO laser cutter, in order to help create the optimum control solution. According to the company’s General Manager, Mr. Lai, “After choosing the NUM CNC system on economic and technical grounds, we were delighted to discover that NUM Taiwan had the engineering expertise and resources, and above all the willingness, to assist us at every stage of design. Thanks to their help, which included developing custom hardware and CNC software, we have been able to bring our new XO high performance laser cutter to market on time and to budget. As a result of reduced development and build costs we have gained an enormous competitive advantage. Our machine is likely to be priced about 20-30 percent below that of comparable machines from Japanese and German manufacturers.”

All motion control elements of the XO laser cutter are supplied by NUM. In addition to the motors, drives and Flexium 68 CNC kernel, the machine uses NUM Ethercat I/O terminals and a dual-processor Flexium FS152i operator panel with a 15-inch flat screen and hard drive, running the Windows operating system. The custom human-machine interface (HMI) was developed entirely by NUM Taiwan, and is highly intuitive and easy to use. Currently available in English as well as traditional and simplified Chinese, the HMI can easily be adapted to other languages to support international sales, and makes extensive use of graphics – including visualization of the workpiece and cutting course – to simplify machine operation and minimize training needs.

The XO laser cutter uses NUM brushless servomotors and NUMDrive C servodrives exclusively. To ensure smooth operation, high inertia BPG series motors are employed for the main X, Y and U positioning axes – the X axis uses two motors – while the Z axis is fitted with a medium inertia BPX series model equipped with a holding brake. The X, Y and Z axes are fully interpolated to provide smooth and continuous control of the cutting head’s position and height above the workpiece. The Z axis has a working range of 100 mm, while the X and Y axes have working lengths of 3 and 1.5 meters respectively. This large working area, combined with an X-Y positioning accuracy of just ±0.01 mm, makes the XO a very versatile machine that is equally capable of precision cutting of multiple small parts, or the cutting of large parts from a single sheet of metal.

A choice of CO2 laser oscillators with power outputs of 3.3, 4 and 6 kW allows machine performance to be matched to the workpiece material, to provide cutting feed rates as high as 60 meters/minute. To maximize its versatility, the machine can also perform a number of specialist metal fabrication functions, including micro welding and micro joining.

During any laser cutting process, the operating conditions can change abruptly, demanding quick adjustment of a large number of parameters to ensure consistent performance. Controlling the power output of the laser oscillator is a particular design challenge – and requires extremely fast and stable communication facilities. To meet these demands, NUM Taiwan developed a special pulse train control card for the CO2 laser oscillator in the XO machine. Implemented entirely in hardware (the use of software would impose unacceptable timing restrictions), the card translates duty cycle and frequency control signals, which are optically coupled to the oscillator to minimize transmission delay. It is suitable for use with many commercial laser oscillators, and can be adjusted for any laser power output from 1 to 10 kW, in 1 kW steps. NUM intends adding the card to its product line in the near future, making it available to other cutting machine manufacturers.

The performance of NUM’s CNC products and the responsiveness of NUM Taiwan has caused Favor Laser to completely re-evaluate its machine control strategy. As well as making exclusive use of NUM hardware and software for its new XO machine, the company intends migrating all its existing product lines over to NUM’s CNC technology. In the first instance, this will involve equipping its range of low cost laser cutters with Flexium 6 or Flexium 8 CNC systems; although these machines will be produced at Favor Laser’s manufacturing plant in China, all CNC support will be provided by NUM Taiwan.

Until now, all of Favor Laser’s machines have been designed for two-dimensional cutting of flat metal sheets, using CO2 laser oscillators. However, the company intends expanding into other areas and is currently looking at fiber lasers with a view to entering the micro-cutting market. These can cut a diverse range of materials such as copper, bronze and aluminum, which is virtually impossible with CO2 lasers. Another project is a laser machine for cutting metal tubes, involving 3D movement with a rotating C axis and a robot head. Within the next year or so, Favor Laser also intends developing a range of punch machines to round out its offering to sheet metal fabricators.

All of these new projects will be based on CNC technology provided by NUM, as Mr. Lai explains: “The exceptional level of support we received from NUM Taiwan during development of the XO laser cutter far exceeded our expectations and produced excellent results. So as well as integrating Flexium systems into our existing product lines, we have decided to base future machines on NUM’s CNC technology. I am confident that our partnership with NUM places Favor Laser in the best possible position to create new laser cutting machine solutions that will benefit our customers.”