Heavy-duty underfloor wheel lathe – flexible and secure, controlled by a NUM CNC

With innovative ideas, secure and dependable technology and NUM as a reliable partner, PMC-Colinet conquers new industrial sectors. Who at the outset could have imagined the international success of the merger between the American company PMC Industries, founded in 1912 in north-east Cleveland, USA, and the Belgian company M.P. Colinet founded in Le Roeulx, Belgium? Since their integration into a group as prestigious as Park Ohio in 1999, PMC-Colinet has been a dominant player in a market where globalization and the oil crisis change the state of play on a daily basis.

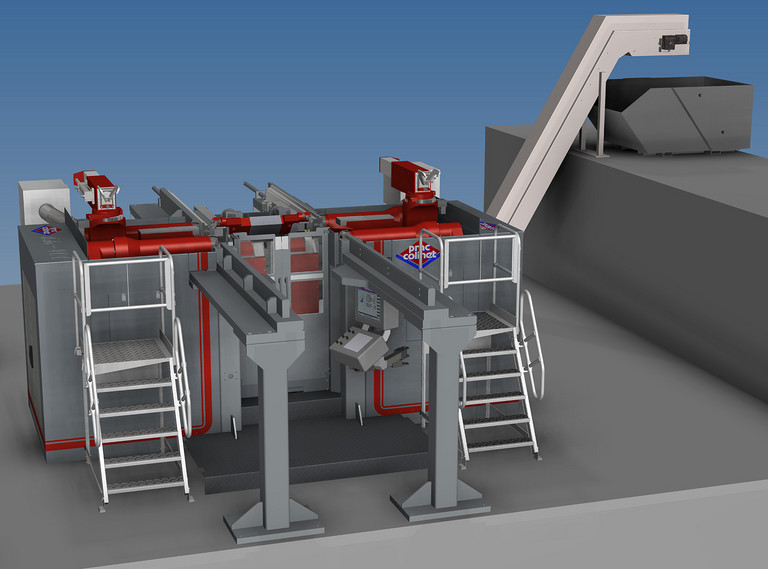

PMC-Colinet continuously meets the challenges of productivity and specialization. Like NUM’s CNC systems, machines bearing the PMC-Colinet trademark are some of the most productive and longest-lived on the market today. When the oil market started to stagnate some years ago, PMC-Colinet began developing machines for other industrial sectors, with a particular focus on the railway industry. The national French railway company SNCF was in need of heavy-duty wheel lathe machines, to maintain their railway engines and wagons. As PMC-Colinet is well known in the rotating tool industry, SNCF asked the company to investigate the feasibility of a heavy-duty wheel lathe machine. Close cooperation between PMC-Colinet, NUM and SNCF has resulted in the development and realization of the heavy-duty underfloor wheel lathe machine shown below. Production of two more machines of this type is currently under negotiation.

Like NUM, PMC-Colinet works closely to meet customers’ needs. Manufacturing, R&D and marketing are performed at both its USA and Belgium locations, enabling the company to respond quickly and effectively anywhere in the world if needed. To understand the success of PMC-Colinet, we must credit the merger of these two formerly private companies and their integration into Park Ohio Corporation. When Park Ohio, an American holding company, was looking to increase its presence in the OCTG (Oil Country Tubular Goods) market, it first acquired PMC Industries, an Ohio-based, specialty machine tool builder with 80+ years in the OCTG business.

MP Colinet, a Belgian lathe builder founded in 1921, was PMC’s main competitor and was also acquired by Park Ohio within months of the PMC acquisition. The merger of PMC and Colinet combines the expertise of the American and Belgian entities into one company that offers tool and product rotating technologies to OCTG customers around the world. Implemented in 1999, this merger encouraged PMC-Colinet’s ambitious growth, backed by the strength of its new owner.

A key advantage for PMC-Colinet is that NUM has collaborated with SNCF for many years, working on a number of highly successful projects. In addition, NUM already has experience of developing and implementing underfloor wheel lathe machines – a few years back the company, together with a partner, realized such a machine for the trams of the municipal transport services of the city of Zurich. These experiences and the expertise gained were useful to build up the new, advanced wheel lathe machine constructed by PMC-Colinet for SNCF and their railroad engines and wagons.

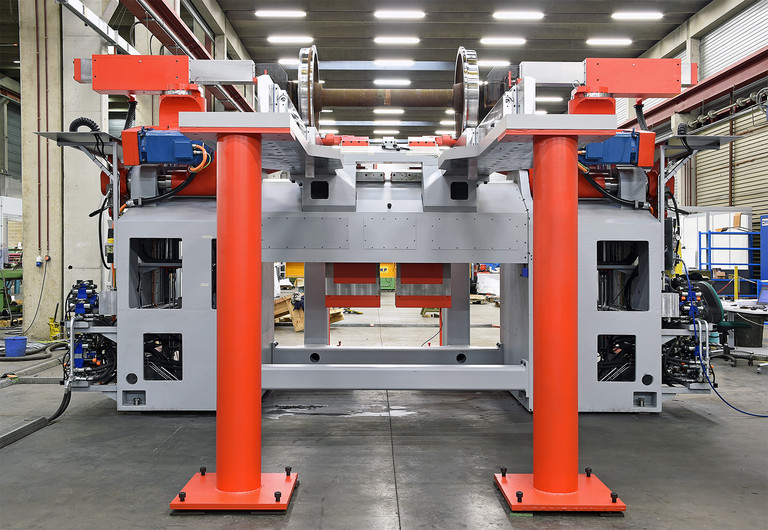

The machine is constructed underfloor, which means that the train engine or wagon can role on to it easily, directly from the railroad tracks. It has adjustable gauge widths and is therefore able to handle trains with gauge widths from 1000 mm up to 1,676 mm. The size of the train wheels’ outside diameter can vary from 500 mm up to 1,600 mm and the maximum weight per train axle (wheel set) is up to 40 tons.

An entire series of wheel sets can be machined regardless of whether they have external or internal bearing boxes – and it also does not matter if they are mechanically connected, or if they are with or without brake discs. Like the wheels, a series of brake discs can be machined – whether they are monolithic or sectored discs fixed on the shaft, or monolithic or sectored discs flanged on the inside or on the outside of the wheel. The weight of this sizable machine is between 25 and 27 tons, dependent on selected options.

The machine is controlled by a CNC system from NUM’s Flexium platform, using NUMDrive C drives and a specially developed 4 axis synchronization facility (2 stations, each with 2 synchronized axis motors per wheel or 4 synchronized axis motors per train axle). PMC-Colinet has developed a special HMI, running within the Flexium system, making the operation of the machine easy and self-explanatory.

“The advantages of NUM CNC include the stability of the system and the easy control handling”, says Mr. Emmanuël Murer, Head of the Engineering Department of the Belgian Unit. In the future, PMC-Colinet intends building all CNC machines in this field with a NUM control system. Of course, the final customers have the last word regarding what kind of CNC control gets mounted on their machines, but the success, the flexibility, the connectivity and the simplicity of using a NUM control system should certainly make the decision easier.

(September 2017)