Major development in thread rolling automation from Italy

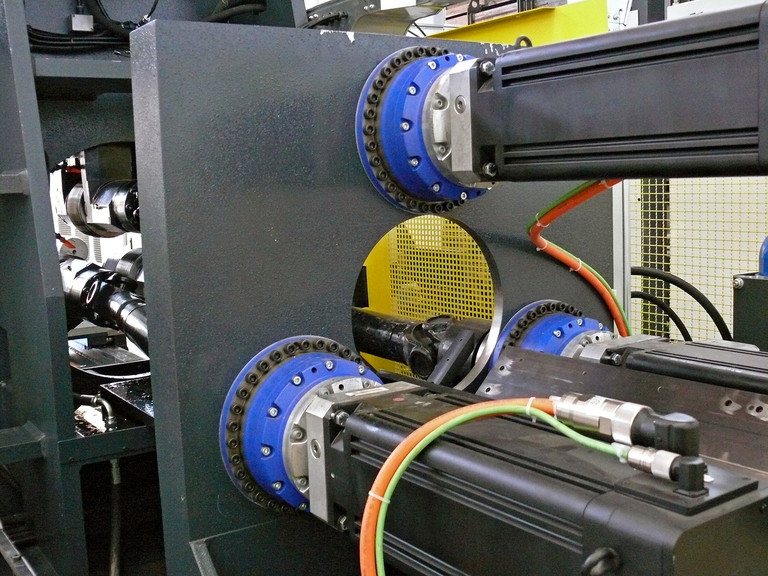

In collaboration with NUM, the Italian machine builder ORT, today owned by MICO S.r.l, and the end user engineering company Cadei have developed an advanced thread rolling machine. The new machine provides improved control and accuracy of the thread penetration process. Thanks to its use of a NUM Flexium CNC system, the machine is also very simple to operate – the necessary skills can be learned very easily and quickly. Almost anyone can now handle the production process, which helps to reduce costs and provides Cadei with a unique competitive advantage.

Engineering company Cadei S.n.c. was founded in 1972 by Giacomino Cadei. Since 2005 the company has been managed by his children, Massimo, Cristian and Michela, who each have more than twenty years of experience in the business.

Cadei primarily specializes in the manufacture of parts for hydraulic molding presses, but its technical know-how also enables the company to provide customers with a diverse range of products, such as component parts for bending equipment, axles for railway rolling stock, and various types of pneumatic and hydraulic machinery. Size is no object and parts can measure up to 650 mm in diameter and 9000 mm in length. Cadei has invested extensively in state-of-the art machine tool technology, including high quality CNC lathes controlled by NUM equipment, to ensure that its products are machined with the utmost precision and reliability. In recent years the company has also developed special skills in the deep hole drilling of cylindrical and other sections, in sizes ranging from 6 mm to 150 mm in diameter.

When it acquired ORT Italia, MICO S.r.l also bought all the intellectual property rights to the company’s range of thread rolling machines (including the machine drawings, commercial component definitions, electrical/hydraulic diagrams, software and market references). MICO now produces these machines and associated spare parts under the trade name of ORT Italia, as well as providing technical support services to end users.

However, MICO’s philosophy extends beyond simply manufacturing and supporting the original ORT machines. The company decided to invest in the automation of the machines to further improve their accuracy and productivity, and to simplify their operation in order to make it less dependent on workers’ experience. MICO also reviewed the machines’ overall structure and mechanical components, with the aim of making them even more robust and reliable.

One of the key benefits of the new machines is an improvement in the accuracy of dynamically controlling thread penetration throughout the thread rolling process. The new automation system enables the mechanical force exerted by the thread rolling dies on the workpiece to be defined and controlled more precisely – which also helps to extend the operational life of the dies. The tilt and shift angles of the dies are calculated automatically (it takes less than five minutes to establish the correct phase, without incurring any loss of workpiece material) and the dies are then moved into position entirely automatically.

All automatically-derived parameters associated with the requested manufacturing cycles for a specific thread (taking into account dimensions and material) can be monitored online. All the steps required for a particular manufacturing sequence can be carried out fully automatically. Particular attention has been paid to the design of a flexible interface, so that any type of dedicated loading system or specialized auxiliary equipment can be easily integrated with the main machine.

With this new thread rolling machine, Cadei is ahead of its competitors. This is not only because of the precise results which can be achieved with this innovative machine, but also due to the fact that it is controlled by a NUM CNC system, which makes it very easy to handle. In fact the control has become so easy, that Cadei can let anyone handle the machine. This simplicity of operation has a major productivity benefit; if an employee is absent their work can easily be handled by someone else, thereby avoiding any downtime in production. “In addition, a consistently high quality final product is guaranteed to the customer at all times,” says Cristian Cadei, Director of Cadei S.n.c.. “Close cooperation with NUM has enabled us to create a highly accurate and easy-to-use machine which brings a competitive advantage to the customer,” says Simone Farina, Technical Chief of ORT.

(September 2014)