ALESA AG: Swiss Precision in Circular Saw Systems and Special Tools

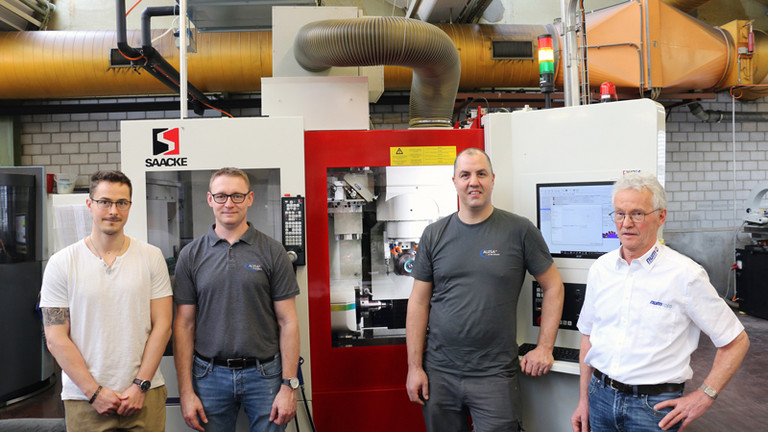

ALESA AG, with its headquarters in Seengen (CH), Aargau, employs around 65 highly motivated and experienced employees and can look back on an impressive tradition in the manufacture of cutting tools that began back in 1934. The family business is now independently managed by the 4th generation. The company’s pride lies in its consistent focus on the highest quality and precision. ALESA has set itself the goal of supplying both the Swiss market and the world market with first-class tools, which are mainly manufactured or resharpened using NUMROTO software. The company is known by end customers as a “problem solver” and consultant who can optimize processes and maximize tool life. This combination of tradition, quality and innovative thinking makes ALESA a reliable partner for sophisticated cutting tool solutions.

Visit website

Visit website

Precise variety

ALESA presents an impressive product portfolio: Circular saw systems and special disk milling cutters which dominate a whopping 40 % of the product range and are manufactured at their production facility in Switzerland. The range also includes 40 % milling heads with indexable inserts, which enables precise milling with a high volume of chip removal. In order to meet the wide range of requirements, a wide range of special tools are available, which make up 20 % of the portfolio. Of course, ALESA AG also offers a comprehensive resharpening service for its tools.

Innovative technologies and quality

ALESA has been successfully using NUMROTO software to manufacture its tools since 2009. The commissioning of the first HAWEMAT machine with NUMROTO was a significant milestone in the company’s technological development. Since then, ALESA’s shop floor has grown considerably, preferably with machines equipped with NUMROTO. The use of this software enables precise and efficient production of tools that meet the highest quality standards.

ALESA optimizes its manufacturing processes through the comprehensive use of the NUMROTO infrastructure. The possibilities of 3D simulation, dressing, in-process measurement and the NR-Control job manager are particularly worth mentioning. The company’s own expertise is also incorporated, particularly in the form of free programming, which is combined with the standard NUMROTO operations and tested as a whole in the 3D simulation. The complete program is then sent to the grinding machine, where everything is ground in a single clamping operation. Mr. Florian Legoll, Application Engineer ALESA, emphasizes: “The 3D simulation makes it possible to precisely predict the production time of a tool too, which makes it much easier to prepare quotations.”

Precise star interfaces and innovative circular saw systems

The circular saw systems in the Nutex family enable precise sawing and slotting on CNC centers without the need for end face clamping elements. This ensures that the circular saws and disk cutters are free on the face side, enabling work pieces to be cut precisely and flatly. The new, patented Nutex Star clamping system complements this. This pioneering, star-shaped star interface enables even greater cutting depths with even greater precision. This clamping system is also ground on NUMROTO machines at ALESA. Daniel Buchmann, Operations Manager at ALESA, emphasizes: “The ability to use NUMROTO on different machine types makes it much easier to train employees. Operators can be deployed on different machines without any problems. Changing a tool series from one machine to another is particularly quick and uncomplicated, even if the machines have different handling systems, such as chain loaders, robots or pallets.”

ALESA’s strategy for tool manufacturing and resharpening

A major advantage of NUMROTO is that the same programs that are developed for tool production can be used in the resharpening centers without any changes.

Increasing demand for circular saws made of ceramic

“Currently, 80 % of ALESA’s tools are made from carbide. The remaining 20 % of our tools are made of high-speed steel (HSS) in order to meet the diverse requirements of our customers”, says Mr. Daniel Buchmann. There is a strong increase in demand from the medical sector for circular saws made of ceramic. In contrast to carbide and high-speed steel (HSS), ceramic does not contain any heavy metals that can be potentially harmful to the human body. ALESA took up this challenge and can now offer optimum solutions for this emerging industry. It is once again setting new standards in tool manufacturing and reaffirming its position as a reliable partner for high-quality and industry-specific solutions.

Synergy ALESA and NUMROTO

Mr. Markus Steiner, Head of the Grinding Department at ALESA, emphasizes: “NUMROTO is an absolute must for the procurement of a new tool grinding machine.” The clear statement emphasizes the essential role of the NUMROTO platform for ALESA’s demanding standards in tool manufacturing. The consistent use of NUMROTO not only reflects technological excellence, but also contributes significantly to the efficiency and precision of the production process.

Circular saw blades for efficient cutting

ALESA’s general expertise in the range of circular saw blades is self-evident. Today, these saws are mainly made of carbide and are used for end products that are particularly difficult to machine or high-alloy end products. In addition to the cylindrical tools, various other forms, such as V-shaped circular saw blades, are also available. Thanks to the individual shaping of the saw blade teeth, they offer a flexible solution for various applications. Thanks to the small diameter of the star interface, the outer diameter of the circular saw blade is reduced while the cutting depth remains the same. As a result, the grinding time and material consumption of such circular saw blades can be significantly reduced.

Special form cutters for the automotive industry

One outstanding example is the special form milling cutter, whose complex form is logarithmically relief-ground and which ensures an important safety function in vehicles in the automotive industry. The high demands of the automotive industry have been fully met with this tool. Tool life was maximized, thanks in part to an ideal rake and relief geometry.

Corner radius cutters for the oil industry

Other interesting tools have been developed for the oil production industry. One such customized special milling cutter with corner radius and special chip breakers, also manufactured with NUMROTO, ensures maximum performance in this demanding environment.

(September 2024)