Established in the market with passion, professionalism and innovative spirit

Developing and manufacturing special tools according to specific customer requirements is the specialty of WAWO, a company based in Oberriet (Switzerland). Founded in 1987 purely as a resharpening company, from the turn of the millennium the focus was on the manufacture of special solid carbide tools and resharpening was concentrated on the company’s own products. The great potential and increasing complexity of these tools were quickly recognized; with NUM and the NUMROTO software, a reliable partner was found to turn even the most demanding tools into reality. The fact that both companies are only half an hour away from each other is further supported by a WAWO company motto: “short, clear communication” is the trump card.

The collaboration between WAWO and NUM began just over a decade ago. Today, WAWO uses NUMROTO software exclusively on several machines from various well-known manufacturers to manufacture tools of all kinds. The focus is clearly on the special solid carbide tools mentioned at the beginning, which are typically manufactured in small batches and used for milling, drilling, turning, reaming, thread cutting, etc. For individual customers, however, large batch orders are also fulfilled, in a 24/7 operation.

WAWO is therefore divided into two divisions. The customers of WAWO Werkzeuge GmbH, where the special solid carbide tools are manufactured, mainly come from the tool and machine construction sectors, the automotive industry, and the medical and vacuum technology sectors. However, special tools from Oberriet are also used in the watch industry. In the European automotive sector, many parts for steering, belt tensioning (as well as other safety components), powertrain and brakes are machined with tools from WAWO. One especially prestigious product line is impact tools, which WAWO grinds for producing gearboxes used in motor racing. In medicine, the tools are used in the manufacture of screws and plates as well as implants for joint replacement.

WAWO Produktion GmbH supplies customers who require medium to large batches of special tools and use them, for example, in the production of high-end furniture, car interiors and fashion articles. These are also manufactured exclusively on machines with NUM controls and NUMROTO software.

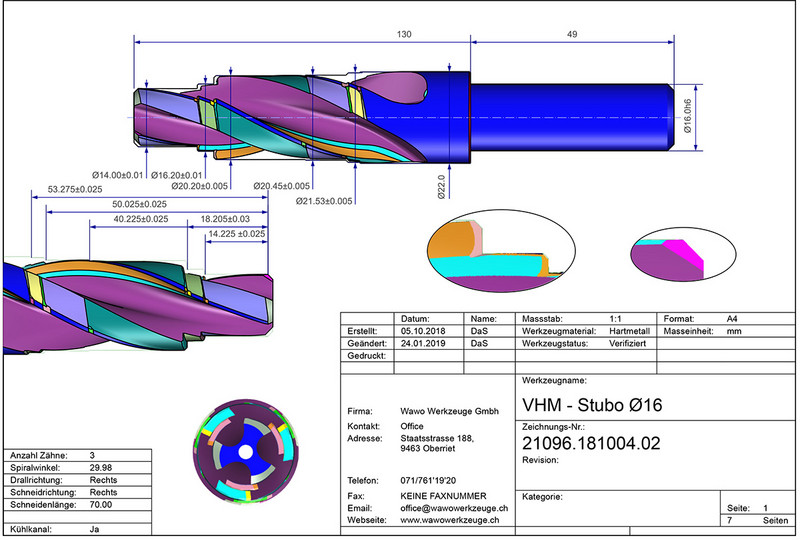

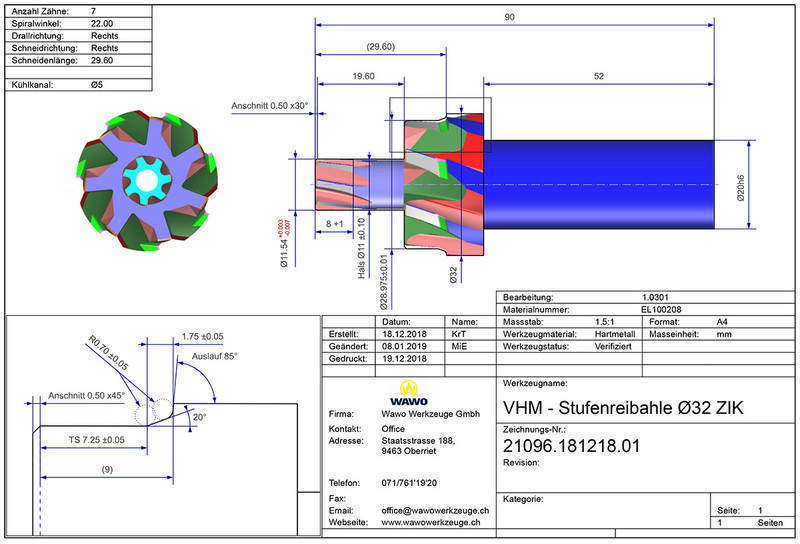

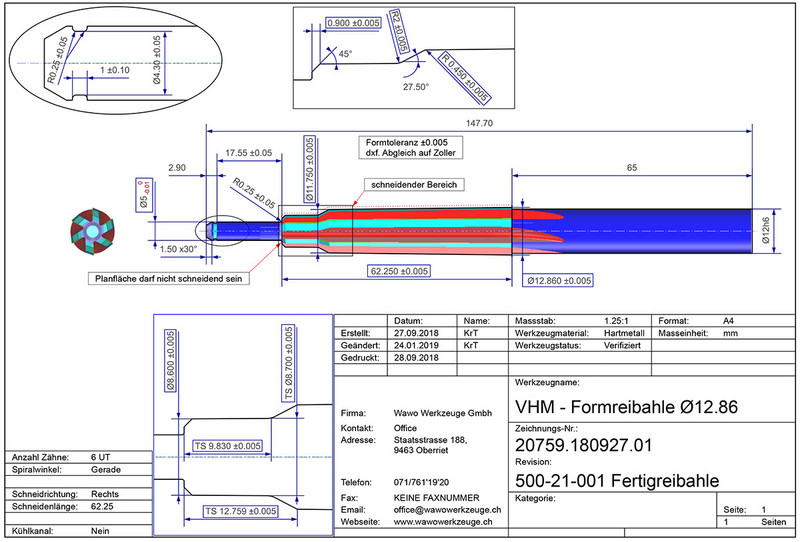

The extraordinary high order rate for proposals created by WAWO is very impressive. A major reason for this high value is the way in which NUMROTO has been fully integrated into the quotation system. According to Adrian Thurnherr, Managing Director of WAWO Werkzeuge GmbH, the deadlines for quotations and implementation are becoming ever shorter. In order to accommodate this trend, WAWO creates a finished NUMROTO program and a complete tool drawing with NUMROTO Draw during the quotation phase. After an inquiry, a customer receives a fully documented quotation with an exact calculation of the price. What initially sounds like additional work saves a lot of time in subsequent production. When the customer gives their “OK”, WAWO can start production immediately. Adrian Thurnherr elaborates on exactly how this is done: “Efficiency can be increased optimally for both sides through clear communication in advance. NUMROTO Draw helps us to check feasibility right from the quotation phase and to identify potential problems at an early stage. This ensures that there are no unpleasant surprises later and the customer gets exactly what they need - including adherence to delivery dates.”

But WAWO offers even more: the small, committed team in the St. Gallen Rhine Valley has a lot of know-how and also dares to tackle very challenging projects. Often the customer only specifies one end product. WAWO analyses this in terms of geometry, material and machining technology, among other things. The required tool is then designed and precisely documented with a keen eye for geometry details such as chip grooves or protective chamfers. The development and production of special tools is thus carried out completely in-house as a service for the end customer.

According to Adrian Thurnherr, the reasons for the exclusive use of NUMROTO are the flexibility of the system and the extensive functions. “NUMROTO offers companies a broad basis for letting their own creativity run wild. We are faced with new tasks every day; NUMROTO is an optimal tool for this and has never confronted us with unsolvable problems within the geometric possibilities.” Daniel Schilling, Application Engineer at WAWO Werkzeuge GmbH, adds: “I like the logical, comprehensible structure. NUMROTO is a reliable tool that makes everything possible. When someone is properly trained on NUMROTO, they can make any tool. Once you know and appreciate NUMROTO, you’ll want to stay with it.”

WAWO goes into every detail with NUMROTO. For example, while chip grooves on sintered inserts are well known, WAWO went one step further in 2018 and developed, among other things, ground chip grooves on form inserts - thus turning steel and steps drills; which until then were not well-known. This is another example of WAWO’s innovation and creativity, supported by NUMROTO.

The development of a special logistics box for the transport and storage of tools also shows that WAWO goes to work with a lot of passion. These are thus not only protected from damage, but can also be optimally stored. “Tools are a high-quality commodity”, Adrian Thurnherr adds. A further, creative solution was found for the use and handling of the products, leading to detail and process optimization, which is important in everyday life.

(September 2019)