STM, one for all – with help from NUM

As a leading supplier and specialist for water jet cutting systems, STM offers a complete service, primarily for companies working in the processing of steel, aluminium, non-ferrous metals, stone, glass, plastic or sealing materials. STM is able to further extend its leading role, with NUM as its competent and solution-oriented partner for CNC control. Based in Bischofshofen, Austria, STM has been developing leading-edge product solutions for more than 20 years.

STM water jet cutting systems bring many advantages as tools for cutting unique forms in almost all materials. Simple programming and control of the water jet, via a highly intuitive MS Windows interface, is standard for STM water jet cutters. The water jet can cut almost all materials with a thickness of 100 mm and greater.

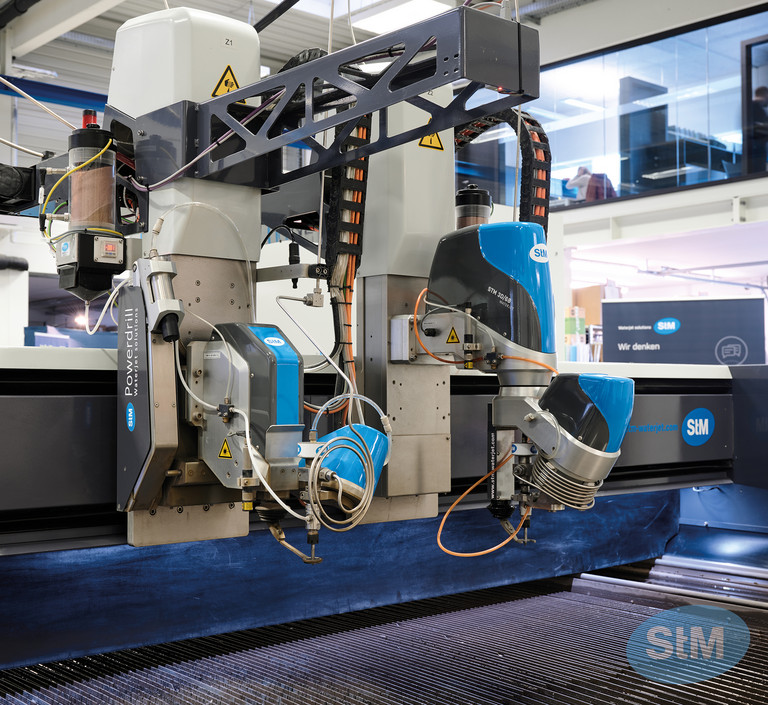

STM manufactures CNC controlled systems in all sizes and for almost any application possible. During design and construction, a great amount of attention is paid to the system’s transportability, ease of use and ease of maintenance, as well as its functionality and cost effectiveness: regardless of the model, all structural parts and screws are made from corrosion-resistant stainless steel or aluminium. The system is extremely manageable and compact, thanks to its flat underbody, smooth side walls using concealed linear guides without bellows, and a high-pressure pipe entrained in the axis. The systems offer a choice of four bridge widths, each available in a range of different lengths, and are divided into three product series: ’EcoCut‘, ’Standard‘ and ’Premium‘. The product series correspond to the most common user profiles in terms of the different technical features they offer. The modular construction of the system guarantees that customers can target their investments in the functions they need at the time, without having to plan far in advance. This makes STM’s systems attractive not just from a technical aspect, but from a cost aspect too.

The fully digitalised drive also contributes to the systems’ cost-effectiveness, with brushless AC servomotors and multi-axis CNC control from NUM, which can process very large amounts of data, even in reload mode. The software for this runs under MS Windows and can be installed and run on standard PCs as often as desired without incurring extra costs. Drawings can be made directly in the cutting program, where the cutting pressure and quantity of abrasives can also be specified very easily. The NUM FS152i P2 operating unit is integrated into a separate control panel, ensuring maximum user comfort, control flexibility and safety. STM only uses top quality high-pressure pumps in its water jet cutting systems. If desired, the system can cut at pressures as high as 6000 bar, with a power requirement of 11 - 75 kW and a flow rate of 1 - 10 litres per minute.

NUM technical specifications:

- Flexium 68 with 7 axes

- FS152i P2, individual keyboard, MP04

- 5-axis interpolation, RTCP (Rotating Tool Centre Point)

- Gantry axes

- Customer-specific application in terms of running and height scanning

- CoDeSys-based, customer-specific HMI

- Digital drive technology with NUMDrive C

There are many different configuration options, depending on the individual requirements. These include automatic height scanning with collision protection, low-pressure monitoring in the abrasive metering system and the option to operate several cutting heads simultaneously. STM presents the whole spectrum of relevant options to a potential customer as part of an individual requirements analysis.

Through continuous advice, training and an extensive replacement parts and maintenance service, STM makes sure that its customers› manufacturing processes remain as profitable as possible for as long as possible. The customer support from STM ranges from technical advice, business planning and sample calculations, to project planning for complete systems, test procedures, shipping and sales training.

Alongside technology for the future and quality as standard, STM puts a particular focus on innovative, complete service. This way, the company can ensure that its customers’ individual production processes can continually be adapted to suit their current requirements.

Through continuous advice, training and an extensive replacement parts and maintenance service, STM makes sure that its customers› manufacturing processes remain as profitable as possible for as long as possible. The customer support from STM ranges from technical advice, business planning and sample calculations, to project planning for complete systems, test procedures, shipping and sales training.

Alongside technology for the future and quality as standard, STM puts a particular focus on innovative, complete service. This way, the company can ensure that its customers’ individual production processes can continually be adapted to suit their current requirements.

(September 2011, updated in 2022)