Successful retrofit for a new life of a Walter Power with NUMROTOplus

The managing director and owner, Mr. Swen Hagelstein, runs his steadily growing company, SOS Elektronik, in Wasserburg at Lake Constance (Germany). The company specializes in bringing old machine tools up to date and making them safe to operate. On the one hand this is to save resources and on the other hand to enable further, long lasting use of the machine. Hagelstein’s experienced and international team overhauls old machines, replaces the CNC controls and brings the power electronics up to the state of the art. The team brings the machines back to life. The retrofit can be performed either at SOS Elektronik’s facility in Wasserburg or directly on-site at customers’ premises.

The retrofit solutions provided by SOS Elektronik are proving a great success. The company offers general overhauls of various machine models, including the Walter Power, the Hawemat 2000 and 3000, and the Schmitt Tempo ETC 502. From the original business idea of worldwide field service for Walter CNC grinding machines, the range of products was quickly expanded thanks to increased demand. It should be emphasized that SOS Elektronik works completely independently and autonomously.

Ready for use again in one-third of the time

In order to conserve resources and save energy and time, SOS Elektronik generally prefers to perform on-site conversion. The preparation of the retrofit takes place at SOS Elektronik, including a preliminary test of the parts to be replaced, after which everything is done at the customer’s site at the machine location. Due to the duration of use of the machines, the machines to be overhauled are often located at the back of production halls, in difficult to access areas. Dismantling and transport usually entails longer downtimes, loss of sales and high transport and customs costs. On-site conversion also avoids customs problems, reduces waiting times and usually no replacement or rental machine is required. With on-site conversion, the machine is ready for use again three times faster than would be the case with dismantling and transport.

Managing Director Mr. Swen Hagelstein talks about the core of the retrofit philosophy: “The machine must be able to do again what it was able to do before, and hopefully a little bit more over the years.” Mr. Hagelstein adds: “I always like to compare it to an old car: the customer has an old 55 hp Golf 2, and wants to keep it. But the engine and transmission are on their last legs. SOS Elektronik installs an engine of this size for him again. That means he has 55 hp again, and still drives a Golf 2. But the car now has some important additional advantages: the new engine is more economical, safer, more environmentally friendly and runs more quietly, even though it remains a Golf 2.”

Convinced by the cooperation

Hagelstein’s professional background is CNC control engineering. Exactly for this reason it was of central importance to him to integrate tool grinding software which is widely established in the market and regarded as standard application software by the industry. After identifying the first projects and interested parties, SOS Elektronik collaborated with NUM to ascertain the best way of breathing new life into the machines. Besides the well-known NUM Flexium+ CNC system, the established NUMROTOplus® application software is used in the ‘old’ machines. NUMROTO is a comprehensive software package for the production and resharpening of various tools that has been available for over 30 years. Nowadays, the software is regarded as a trendsetter and is also the market leader in tool grinding – worldwide. Innovative high-tech solutions, flexible and versatile application possibilities, continuous development and comprehensive user know-how have always guaranteed quality and economy for all standard and special tools.

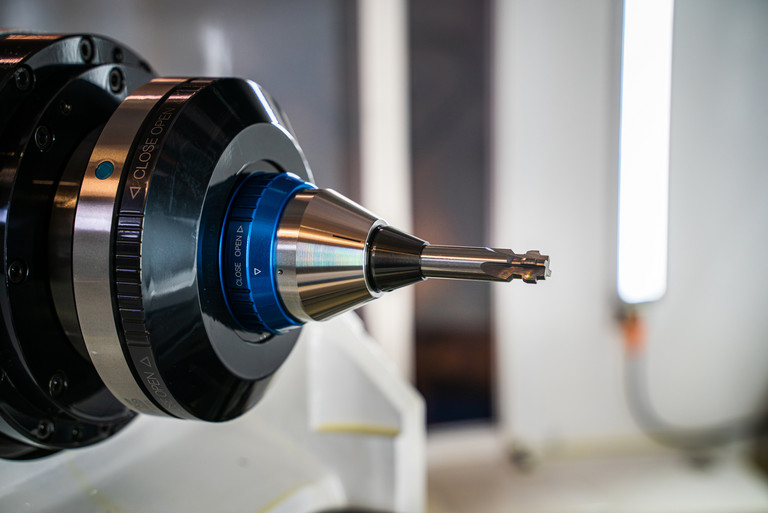

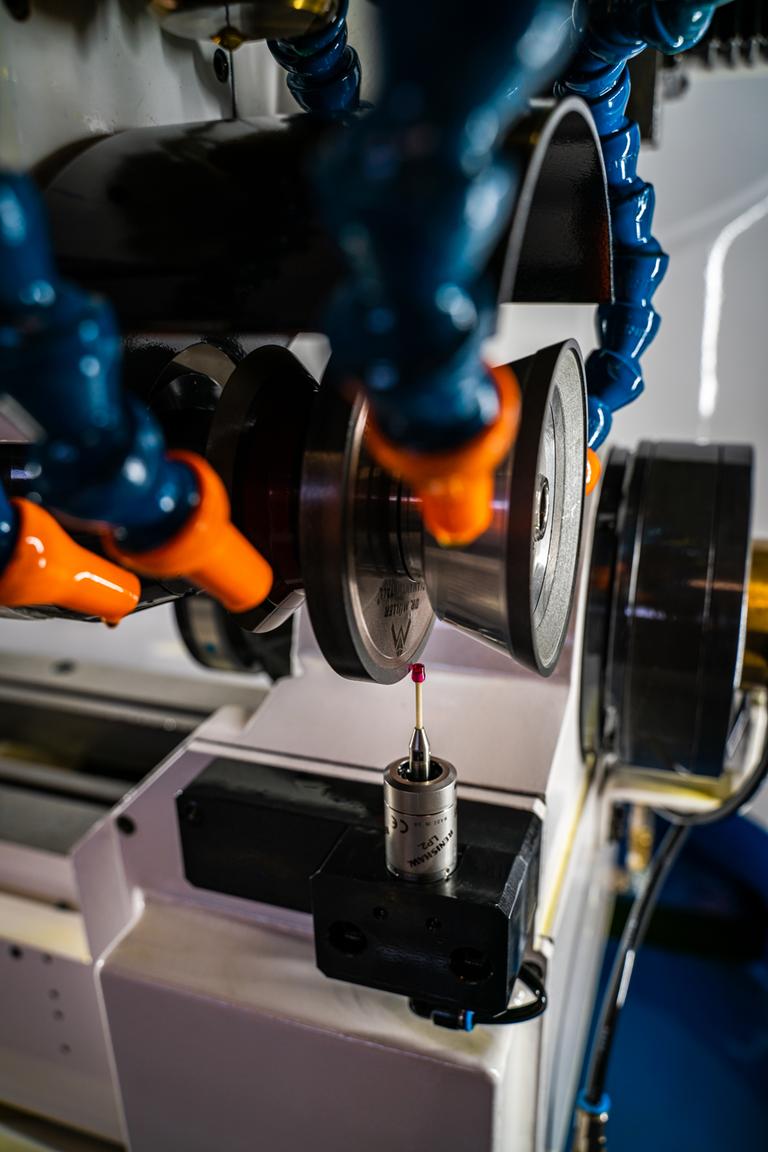

As Area Sales Manager of NUM Switzerland, Ralph Jacobs, comments: “Two parallel worlds have found each other here and complement each other perfectly. The physical proximity of SOS and NUM means that many things can be implemented quickly, but the mutual gain in know-how is also remarkable.” A good and solid basis for cooperation was thus quickly established. The first retrofit of a used power regrinder to a NUM CNC control system was implemented and successfully put into operation within a short time. According to Jacobs, the first grinding tests on this reconditioned Power Machine have already shown remarkable results. The complete rebuild to the new NUM CNC control package uses the latest NUM safety architecture and therefore the machine complies with today’s safety regulations. In addition to the installation of the NUM CNC and NUMROTO software, the Power Machine has been considerably expanded in its range of functions and performance by the additional installation of tool and disk probes, and optimized for future applications.

With the future in mind

In times when sustainability is of great importance and trendsetting for the coming generations, SOS Elektronik focuses on the appropriate business field. The machines are given a second life and the production at the end customer’s premises can continue as usual or even be increased. Initially, the widely used Walter Power Regrinder series was revised. In the future, however, retrofits for the Walter Classic and Mini series, as well as an optional loader or robot system, are also planned. Extending the service life for additional years by retrofitting an existing machine makes economic sense, especially in today’s competitive markets, where production costs are becoming increasingly important.

(September 2020)