Precision 3D water jet cutting guarantees top quality results

Global company Perndorfer Maschinenbau KG specializes in water jet cutting, water jet cutting systems and water jet cutting machines. Perndorfer’s products include high-technology CNC-controlled 2D and 3D water jet cutters. Together with NUM, it has now built a five-axis water jet cutting system which can process large workpieces with external dimensions of up to 9000 × 4000 mm very efficiently and accurately.

Founded in 1985 by owner Franz Perndorfer, Perndorfer Maschinenbau KG is now one of the most innovative companies in the industry. With around 60 qualified employees, Perndorfer is permanently and successfully engaged in the international market and demonstrates ongoing competitiveness based on innovation, precision and quality. Its cooperation with NUM started around 20 years ago and has grown constantly since.

Decades of experience in the design, development and production of CNC-controlled water jet cutting systems and special machine construction enable Perndorfer to offer a wide range of products and services in this technology sector. Specific customer requirements are flexibly and capably implemented in close cooperation with NUM. This includes prototype construction through to the provision of complete solutions and individually customized systems, as well as training, specific on-site consultancy and 24-hour service.

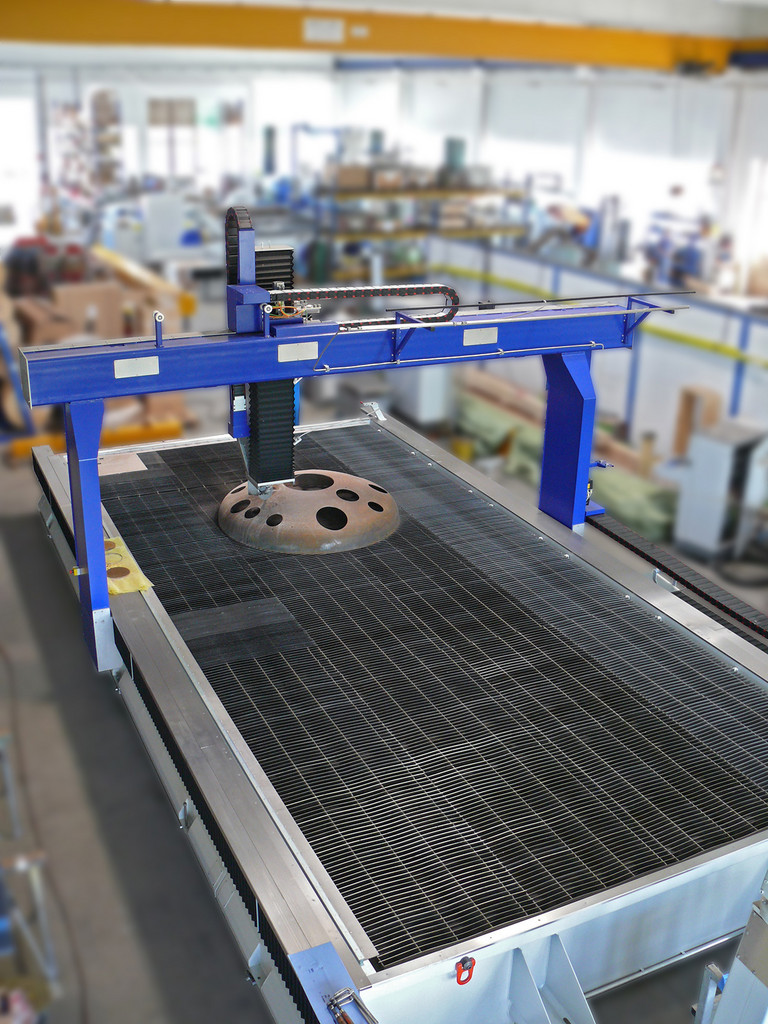

The machine shown here is a five-axis water jet cutting system which can cut through steel with a thickness of up to 140 mm and aluminum with a thickness of up to 180 mm very efficiently, using just water and suitable abrasive material at a pressure of 4000 bar. The bottom end cap of a pressure tank shown here is made of 6 mm thick steel and can be cut precisely at 330 mm per minute. The cut can be programmed to any angle required. This makes it possible to cut facets on three dimensional preformed parts, in preparation for the subsequent welding on of other components such as flanges, pipes, heat exchangers, etc. This guarantees efficient workflows.

This machine can be used to cut workpieces with maximum lateral dimensions of 9000 × 4000 mm and heights of up to 500 mm. Customers are free to choose the working height to suit their requirements at the machine design stage; this then determines the appropriate height for the portal that supports the Z axis and the 3D cutting head.

It is therefore suitable for 2D sheet cutting of any kind, or for 3D cutting of various workpieces such as pipes, containers or covers for pressure tanks, like the end caps which can be seen in the pictures. The machine can also be configured for welding applications; it is designed to accept a five-axis welding head as an alternative to water cutting jets.

The workpieces are placed on the table to allow optimum processing with the CNC-controlled five-axis cutting head from all sides. This water jet cutting machine is fitted with the NUM Flexium CNC system with six axes, gantry function as well as water jet and five-axis technology. For both Perndorfer and NUM it is important to implement a complete solution. This is the only way to guarantee the quality of all working stages and produce a high-precision, high-quality end result. The cooperation between Perndorfer and NUM involves close dialog from the very start of a project, i.e. from design through to approval and commissioning of the machine on the customer’s site. It goes without saying that the company provides capable, smooth services for many years after acceptance of the machine by the customer.

The precise, high-quality end product provided to the customers in the form of a Perndorfer machine with a NUM CNC system guarantees them a competitive advantage in their market. This competitive advantage is both objective and motivation for Perndorfer and NUM.

(September 2014)