25 Years of MKM International GmbH: Customized Solutions and Customer-Oriented Partnerships

East Westphalian-based MKM International GmbH is celebrating an important anniversary this year — 25 years of successful operation in the field of CNC special plant engineering. Since its founding by Michael Köhler in 1999, the company has become a leading supplier of innovative, directly-sold CNC systems. From the start, MKM, with a dedicated team of now 60 employees, has focused on customized, modular products to meet its customers individual requirements. MKM has continuously evolved and specialized, from developments in entry-level machines for solid wood processing to the manufacture of systems for processing complex materials such as plastics, light metals, or composites.

Visit website

Visit website

The Path to Success: Customer Centricity and Transparent Communication

MKM’s success story is based not only on its development of high-quality, specialized CNC systems but also on a philosophy of partnership where MKM pursues an extraordinarily strong customer orientation as an ideas and solutions provider. By involving customers early in the development process, using clear, competent communication and short decision-making paths, and relying upon modular system segments, fast and reliable solutions are created—all focused on maximum customer satisfaction and reliability.

Long-term Partnership: Continuity, Technology Reliability, and Customer Satisfaction

MKM and NUM look back on a long-standing partnership. This partnership enables MKM to obtain spare parts and carry out repairs at any time, even after 25 years. Together, MKM and NUM maintain a full spare parts service for every MKM machine supplied to the market to date. The openness, simplicity, and exceptional sustainability of NUM CNC systems have enabled MKM to meet even the most demanding customer requirements and develop innovative solutions that set new standards. The high reliability of the technology, long-term spare parts availability, and high stock levels ensure continuous machine operation. This cooperation enables MKM to meet the growing demands of its customers.

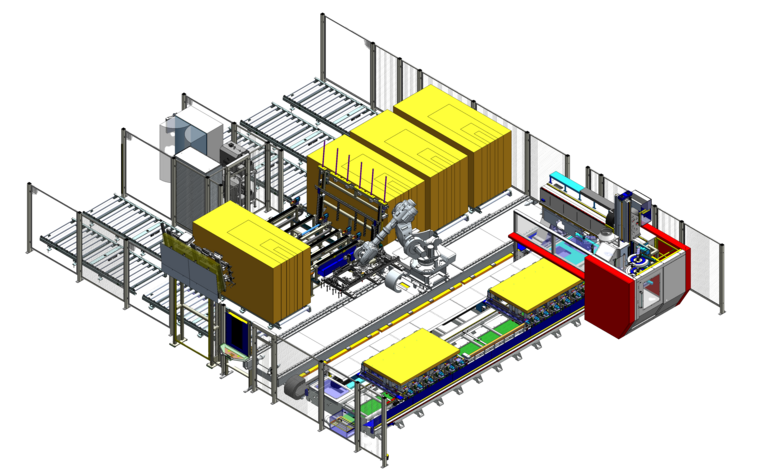

Universal System with Robot Automation

An outstanding example of the successful cooperation between NUM and MKM is the development of a special machine with 3 CNC controls, 6 power supply groups, 50 axes, 12 spindles, and 14 channels. This machine, equipped with a NUM CNC control, showcases the innovative strength and technical expertise of both companies.

Another highlight in MKM’s product portfolio is a stationary universal system for door leaves with robot automation. Also equipped with a NUM CNC system, this machine enables fully automated door processing in extremely confined spaces, setting new standards in efficiency and precision. Pendulum processing allows production on one side of the machine while the other is being set up; transitions take mere seconds. The new HMI FS184 and the Machine Panel MP07 are in use and installed in duplicate to enable operation from both sides. The system is designed for unmanned production but can also be run manually by an operator.

The Future of CNC Plant Engineering

MKM sees NUM as more than a supplier, as a strategic partner for the future. Together, the two companies set new benchmarks and implement innovative ideas. This partnership is based on a shared corporate culture and effective communication, enabling short paths and promoting efficient cooperation.

Mr. Holger Blötscher, Managing Director of MKM, emphasizes the importance of the partnership with NUM: “The cooperation with NUM enables us to push the boundaries of what is technically feasible and to meet the highest demands of our customers. We see NUM as a partner for the future and look forward to further successful projects.”

MKM International GmbH is celebrating not only 25 years of successful business but also looks optimistically toward the future—with NUM by its side as a partner for further innovative developments in CNC system engineering. Mr. Blötscher emphasizes the importance of the cooperation with NUM: “With NUM, we design ideas that can also be implemented. Together we set new benchmarks and drive innovation in CNC system engineering.”

(September 2024)