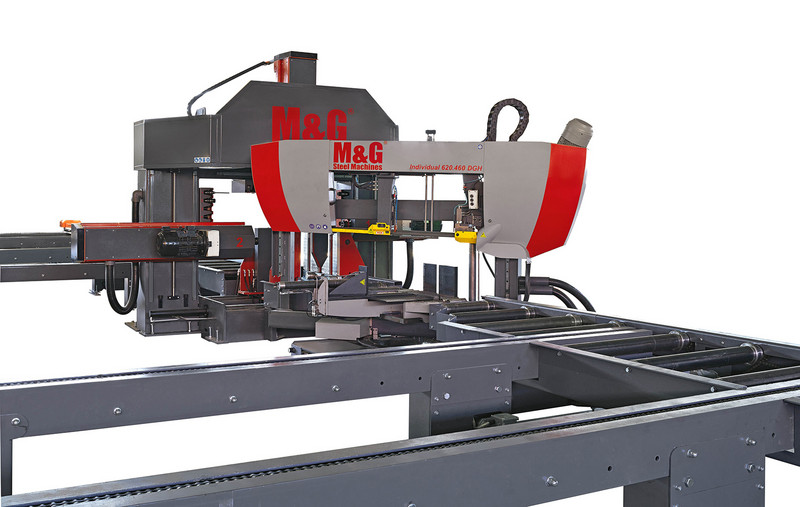

CNC drilling and sawing processing center for steel beams and profiles

For Adunguem, as for NUM, it is essential that our equipment provides a quick and efficient solution which is adapted to the needs of both, customers and partners. Adunguem’s M and G Steel Machine brand presents a complete solution that meets all of these needs, functionally designed for each client. Adunguem is also focused to providing it’s customers with extremely responsive service and support through the total machine life cycle. A key element and essential cornerstone critical in the development of enterprises. Adunguem’s intensions are to be at the forefront with regard to creating equipment for the metal industry – using the latest technology and in line with new developments in the market.

Registered and approved as a national brand, M&G Steel Machines presents the unique equipment, designed and manufactured in Paços de Ferreira, Portugal. The machine shown here is the only beam and profile processing center produced in Portugal.

This steel processing center has a system for drilling, threading, marking and other operations of profiles with three heads and a CNC system, powered by a NUM Flexium CNC unit. This is an ideal processing center for steel stockholders and structural steel builders with large production outputs and requiring very versatile machining capabilities. The high accuracy of the pusher is reached by moving it by a servo motor with integrated measuring system. This product line provides three heads for drilling up to 40 mm in diameter. HSS drill bits can be used as well as hard metal bits which enable drilling at greater speeds.

Equipped with the NUM Flexium CNC system’s touch screen, which operates under the Windows environment, the machine’s operation is very intuitive, which dramatically reduces the user’s learning curve. It is fully compatible with all the major CAD/CAM systems on the market, as well as DSTV files. The conveyer elements accommodates 250 mm rolls and has a short distance between them, in order to stabilize and better direct the bar. This system prevents the materials colliding with the structure of the store at the time of movement.

The machine’s innovative design allows attractively reduced dimensions, reduces handling time and consequently enhances global processing speed.

(September 2017)