Flexium powers new aerospace centreless grinder

The UK-based grinding specialist RefreshEng has launched a re-engineered centreless grinder based on one of the world‘s most widely-used machines, with the aid of software development support from NUM. The upgrade converts any of the veteran Cincinnati 2-OM family of machines to the same kind of automated and precision machining available on state-of-the-art centreless grinders - but for an outlay that is some 60% lower than a new machine.

The upgrades transform the 2-OM‘s original hydraulic- and mechanical-dressing architecture - with its fixed cam-and-stylus control - to an advanced CNC software-based system with up to seven axes of servomotor-based motion depending on customer choices. Initially, the new machine is targeted at the aerospace industry, and comes with application-specific software to automate the production of the specialist countersink, button-head and relief style fasteners used in aviation fuselage and engine production.

To complete the automation upgrade RefreshEng incorporates numerous advanced features. These include acoustic sensors that automatically monitor and compensate for grinding wheel wear. The sensing system is also used to dynamically adjust grinding wheel feedrate to provide ‚gap elimination‘; this feature alone can reduce grinding cycle times by almost 20% across a batch of raw material parts. Higher resolution control of movement, and the ability to interpolate movement, improves both grinding accuracy and extends the range of shapes that can be ground. The grinding wheel has been fitted with a dynamic balancing system. Wheel speed can also be varied to suit different materials. Another key feature is a choice of drop-, finger- or front-loading autoloaders.

This idea for the project span out of RefreshEng‘s intimate knowledge of the centreless grinding business, derived from its established tooling services in the UK and Europe. Many of its clients wanted to re-control their old machines to an advanced level, to increase throughput and eliminate manual operations, but found it difficult to source the technical support for such work. RefreshEng recognised the opportunity, especially for the popular Cincinnati 2-OM, as it estimates there are still some 2000 of these machines in the UK alone.

RefreshEng‘s staff - who have grinding machine design experience - had clear ideas of how to update the mechanical architecture. This involved the replacement of hydraulics in favour of servomotor-controlled motion, with numerous modifications to the underlying framework including new castings to mount the electro-mechanics. The key hurdle for RefreshEng‘s CEO Damian Clements was finding a CNC supplier that would be prepared to complement his company‘s know-how with high-level control system software skills. In order to make the project financially viable, RefreshEng also wanted the CNC supplier to defer the return on their development efforts until sales of the machine started to build. Previous good experience with NUM led Clements to discuss the project first with the NUM UK. NUM offered to act as a virtual partner, allowing its programming staff to work alongside RefreshEng‘s staff as a development team.

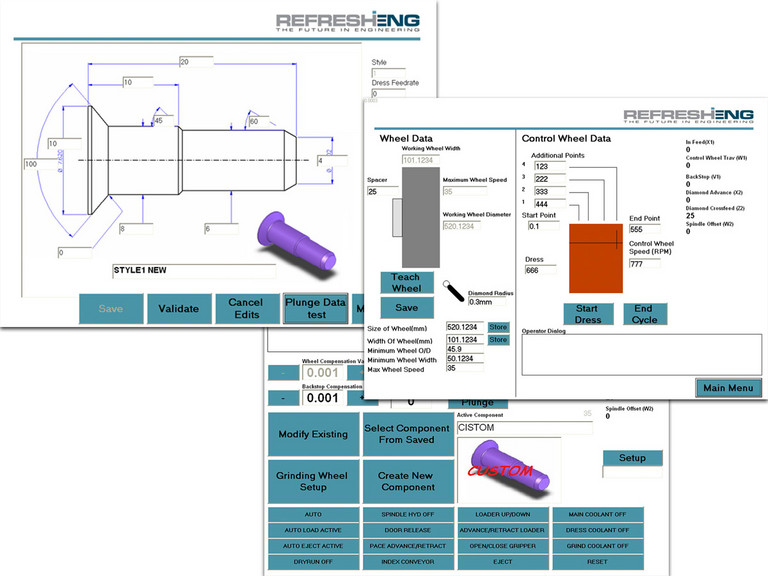

RefreshEng provided NUM with flow charts of the way it wanted the new machine to function, so that the control logic and operator interface software could be developed. The companies‘ engineers then worked together - often using internet communications to link remotely to the prototype - to realise and test the new control system. Even though the type of custom HMI RefreshEng wanted was seemingly fresh to this type of machine, NUM‘s software developers completed the work within just 3-4 man-months. The open programmability of Flexium‘s man-machine interface was the catalyst for this rapid design cycle. In addition to providing the control structure, NUM also exploited the HMI programmability to generate a distinctive look-and-feel for the control software - to simplify use and to start building a brand feel for RefreshEng‘s entry into the grinding machinery market.

NUM‘s software employs dialog boxes to simplify programming - allowing new grinding profiles to be created in under a minute. The operator simply populates data fields on a sequence of screens, which include graphical representations of the fastener style, and the profile is automatically generated. Parts can then be produced completely automatically, with the machine‘s software also automatically performing housekeeping tasks such as dressing the wheel.

The hardware is based on the economic Flexium 68 CNC kernel, with an FS152i touch-screen HMI, machine panel with handwheel for operator programming and control, plus MDLU3 drives and BPX servomotors with absolute encoders. The axes controlled (depending on machine model) are control wheel-infeed, -traverse and -rotation, dresser-infeed and -traverse, backstop and spindle lateral adjust.

„This project exemplifies the way NUM likes to work,“ says Steve Moore of NUM UK. „Because our business is built on helping small to medium sized machine builders to compete, we have invested in a decentralised R&D structure which locates engineering staff all around the world, and we are very willing to customise our CNC technology to support clients.“

(September 2013)